diff --git a/.github/ISSUE_TEMPLATE/bug_report.md b/.github/ISSUE_TEMPLATE/bug_report.md

new file mode 100644

index 00000000..3d352a1b

--- /dev/null

+++ b/.github/ISSUE_TEMPLATE/bug_report.md

@@ -0,0 +1,29 @@

+---

+name: Bug report

+about: Create a report to help us improve

+title: "[BUG]"

+labels: possible bug

+assignees: ''

+

+---

+

+This is a simplified template, feel free to change it if it does not fit your case.

+

+**Describe the bug**

+A clear and concise description of what the bug is.

+

+**Describe the hardware setup**

+For us it is very important to know what is the hardware setup you're using in order to be able to help more directly

+- Which motor

+- Which driver

+- Which microcontroller

+- Which position sensor

+- Current sensing used?

+

+**IDE you are using**

+- Arduino IDE

+- Platformio

+- Something else

+

+**Tried the Getting started guide? - if applicable**

+Have you tried the getting started guide and at which step are you blocked in

diff --git a/.github/ISSUE_TEMPLATE/feature_request.md b/.github/ISSUE_TEMPLATE/feature_request.md

new file mode 100644

index 00000000..df558478

--- /dev/null

+++ b/.github/ISSUE_TEMPLATE/feature_request.md

@@ -0,0 +1,20 @@

+---

+name: Feature request

+about: Suggest an idea for this project

+title: "[FEATURE]"

+labels: enhancement

+assignees: ''

+

+---

+

+**Is your feature request related to a problem? Please describe.**

+Description of what the problem is. Ex. I'm always frustrated when [...]

+

+**Describe the solution you'd like**

+Description of what you want to happen.

+

+**Describe alternatives you've considered**

+Description of any alternative solutions or features you've considered.

+

+**Additional context**

+Add any other context or screenshots about the feature request here.

diff --git a/.github/workflows/ccpp.yml b/.github/workflows/ccpp.yml

index 6171ab77..b4830d82 100644

--- a/.github/workflows/ccpp.yml

+++ b/.github/workflows/ccpp.yml

@@ -12,16 +12,19 @@ jobs:

- arduino:sam:arduino_due_x # arduino due

- arduino:samd:nano_33_iot # samd21

- adafruit:samd:adafruit_metro_m4 # samd51

- - esp32:esp32:esp32doit-devkit-v1 # esm32

- - STM32:stm32:GenF1:pnum=BLUEPILL_F103C8 # stm32 bluepill

- - STM32:stm32:Nucleo_64:pnum=NUCLEO_F411RE # stm32 nucleo

+ - esp32:esp32:esp32doit-devkit-v1 # esp32

+ - esp32:esp32:esp32s2 # esp32s2

+ - STMicroelectronics:stm32:GenF1:pnum=BLUEPILL_F103C8 # stm32 bluepill

+ - STMicroelectronics:stm32:Nucleo_64:pnum=NUCLEO_F411RE # stm32 nucleo

+ - STMicroelectronics:stm32:GenF4:pnum=GENERIC_F405RGTX # stm32f405 - odrive

+ - STMicroelectronics:stm32:Disco:pnum=B_G431B_ESC1 # B-G431-ESC1

- arduino:mbed_rp2040:pico # rpi pico

include:

- arduino-boards-fqbn: arduino:avr:uno # arudino uno - compiling almost all examples

sketch-names: '**.ino'

required-libraries: PciManager

- sketches-exclude: bluepill_position_control, esp32_position_control, esp32_i2c_dual_bus_example, stm32_i2c_dual_bus_example, magnetic_sensor_spi_alt_example, osc_esp32_3pwm, osc_esp32_fullcontrol, nano33IoT_velocity_control, smartstepper_control,esp32_current_control_low_side, stm32_spi_alt_example, esp32_spi_alt_example, B_G431B_ESC1_position_control

+ sketches-exclude: bluepill_position_control, esp32_position_control, esp32_i2c_dual_bus_example, stm32_i2c_dual_bus_example, magnetic_sensor_spi_alt_example, osc_esp32_3pwm, osc_esp32_fullcontrol, nano33IoT_velocity_control, smartstepper_control,esp32_current_control_low_side, stm32_spi_alt_example, esp32_spi_alt_example, B_G431B_ESC1, odrive_example_spi, odrive_example_encoder, single_full_control_example, double_full_control_example

- arduino-boards-fqbn: arduino:sam:arduino_due_x # arduino due - one full example

sketch-names: single_full_control_example.ino

@@ -36,17 +39,29 @@ jobs:

platform-url: https://adafruit.github.io/arduino-board-index/package_adafruit_index.json

sketch-names: single_full_control_example.ino

+ - arduino-boards-fqbn: esp32:esp32:esp32s2 # esp32s2

+ platform-url: https://raw.githubusercontent.com/espressif/arduino-esp32/gh-pages/package_esp32_dev_index.json

+ sketch-names: bldc_driver_3pwm_standalone.ino, stepper_driver_2pwm_standalone.ino, stepper_driver_4pwm_standalone

+

- arduino-boards-fqbn: esp32:esp32:esp32doit-devkit-v1 # esp32

- platform-url: https://dl.espressif.com/dl/package_esp32_index.json

+ platform-url: https://raw.githubusercontent.com/espressif/arduino-esp32/gh-pages/package_esp32_dev_index.json

sketch-names: esp32_position_control.ino, esp32_i2c_dual_bus_example.ino, esp32_current_control_low_side.ino, esp32_spi_alt_example.ino

- - arduino-boards-fqbn: STM32:stm32:GenF1:pnum=BLUEPILL_F103C8 # bluepill - hs examples

- platform-url: https://github.com/stm32duino/BoardManagerFiles/raw/master/STM32/package_stm_index.json

+ - arduino-boards-fqbn: STMicroelectronics:stm32:GenF1:pnum=BLUEPILL_F103C8 # bluepill - hs examples

+ platform-url: https://github.com/stm32duino/BoardManagerFiles/raw/main/package_stmicroelectronics_index.json

sketch-names: bluepill_position_control.ino, stm32_i2c_dual_bus_example.ino, stm32_spi_alt_example.ino

+

+ - arduino-boards-fqbn: STMicroelectronics:stm32:Disco:pnum=B_G431B_ESC1 # B-G431-ESC1

+ platform-url: https://github.com/stm32duino/BoardManagerFiles/raw/main/package_stmicroelectronics_index.json

+ sketch-names: B_G431B_ESC1.ino

+

+ - arduino-boards-fqbn: STMicroelectronics:stm32:GenF4:pnum=GENERIC_F405RGTX # stm32f405 - odrive

+ platform-url: https://github.com/stm32duino/BoardManagerFiles/raw/main/package_stmicroelectronics_index.json

+ sketch-names: odrive_example_encoder.ino, odrive_example_spi.ino

- - arduino-boards-fqbn: STM32:stm32:Nucleo_64:pnum=NUCLEO_F411RE # one full example

- platform-url: https://github.com/stm32duino/BoardManagerFiles/raw/master/STM32/package_stm_index.json

- sketch-names: single_full_control_example.ino, stm32_spi_alt_example.ino

+ - arduino-boards-fqbn: STMicroelectronics:stm32:Nucleo_64:pnum=NUCLEO_F411RE # nucleo one full example

+ platform-url: https://github.com/stm32duino/BoardManagerFiles/raw/main/package_stmicroelectronics_index.json

+ sketch-names: single_full_control_example.ino, stm32_spi_alt_example.ino, sdouble_full_control_example.ino

diff --git a/CODE_OF_CONDUCT.md b/CODE_OF_CONDUCT.md

new file mode 100644

index 00000000..88763e95

--- /dev/null

+++ b/CODE_OF_CONDUCT.md

@@ -0,0 +1,128 @@

+# Contributor Covenant Code of Conduct

+

+## Our Pledge

+

+We as members, contributors, and leaders pledge to make participation in our

+community a harassment-free experience for everyone, regardless of age, body

+size, visible or invisible disability, ethnicity, sex characteristics, gender

+identity and expression, level of experience, education, socio-economic status,

+nationality, personal appearance, race, religion, or sexual identity

+and orientation.

+

+We pledge to act and interact in ways that contribute to an open, welcoming,

+diverse, inclusive, and healthy community.

+

+## Our Standards

+

+Examples of behavior that contributes to a positive environment for our

+community include:

+

+* Demonstrating empathy and kindness toward other people

+* Being respectful of differing opinions, viewpoints, and experiences

+* Giving and gracefully accepting constructive feedback

+* Accepting responsibility and apologizing to those affected by our mistakes,

+ and learning from the experience

+* Focusing on what is best not just for us as individuals, but for the

+ overall community

+

+Examples of unacceptable behavior include:

+

+* The use of sexualized language or imagery, and sexual attention or

+ advances of any kind

+* Trolling, insulting or derogatory comments, and personal or political attacks

+* Public or private harassment

+* Publishing others' private information, such as a physical or email

+ address, without their explicit permission

+* Other conduct which could reasonably be considered inappropriate in a

+ professional setting

+

+## Enforcement Responsibilities

+

+Community leaders are responsible for clarifying and enforcing our standards of

+acceptable behavior and will take appropriate and fair corrective action in

+response to any behavior that they deem inappropriate, threatening, offensive,

+or harmful.

+

+Community leaders have the right and responsibility to remove, edit, or reject

+comments, commits, code, wiki edits, issues, and other contributions that are

+not aligned to this Code of Conduct, and will communicate reasons for moderation

+decisions when appropriate.

+

+## Scope

+

+This Code of Conduct applies within all community spaces, and also applies when

+an individual is officially representing the community in public spaces.

+Examples of representing our community include using an official e-mail address,

+posting via an official social media account, or acting as an appointed

+representative at an online or offline event.

+

+## Enforcement

+

+Instances of abusive, harassing, or otherwise unacceptable behavior may be

+reported to the community leaders responsible for enforcement at

+info@simplefoc.com.

+All complaints will be reviewed and investigated promptly and fairly.

+

+All community leaders are obligated to respect the privacy and security of the

+reporter of any incident.

+

+## Enforcement Guidelines

+

+Community leaders will follow these Community Impact Guidelines in determining

+the consequences for any action they deem in violation of this Code of Conduct:

+

+### 1. Correction

+

+**Community Impact**: Use of inappropriate language or other behavior deemed

+unprofessional or unwelcome in the community.

+

+**Consequence**: A private, written warning from community leaders, providing

+clarity around the nature of the violation and an explanation of why the

+behavior was inappropriate. A public apology may be requested.

+

+### 2. Warning

+

+**Community Impact**: A violation through a single incident or series

+of actions.

+

+**Consequence**: A warning with consequences for continued behavior. No

+interaction with the people involved, including unsolicited interaction with

+those enforcing the Code of Conduct, for a specified period of time. This

+includes avoiding interactions in community spaces as well as external channels

+like social media. Violating these terms may lead to a temporary or

+permanent ban.

+

+### 3. Temporary Ban

+

+**Community Impact**: A serious violation of community standards, including

+sustained inappropriate behavior.

+

+**Consequence**: A temporary ban from any sort of interaction or public

+communication with the community for a specified period of time. No public or

+private interaction with the people involved, including unsolicited interaction

+with those enforcing the Code of Conduct, is allowed during this period.

+Violating these terms may lead to a permanent ban.

+

+### 4. Permanent Ban

+

+**Community Impact**: Demonstrating a pattern of violation of community

+standards, including sustained inappropriate behavior, harassment of an

+individual, or aggression toward or disparagement of classes of individuals.

+

+**Consequence**: A permanent ban from any sort of public interaction within

+the community.

+

+## Attribution

+

+This Code of Conduct is adapted from the [Contributor Covenant][homepage],

+version 2.0, available at

+https://www.contributor-covenant.org/version/2/0/code_of_conduct.html.

+

+Community Impact Guidelines were inspired by [Mozilla's code of conduct

+enforcement ladder](https://github.com/mozilla/diversity).

+

+[homepage]: https://www.contributor-covenant.org

+

+For answers to common questions about this code of conduct, see the FAQ at

+https://www.contributor-covenant.org/faq. Translations are available at

+https://www.contributor-covenant.org/translations.

diff --git a/README.md b/README.md

index c0e019d6..25c728a5 100644

--- a/README.md

+++ b/README.md

@@ -4,6 +4,7 @@

[](https://opensource.org/licenses/MIT)

[](https://www.ardu-badge.com/badge/Simple%20FOC.svg)

+[](https://joss.theoj.org/papers/4382445f249e064e9f0a7f6c1bb06b1d)

We live in very exciting times 😃! BLDC motors are entering the hobby community more and more and many great projects have already emerged leveraging their far superior dynamics and power capabilities. BLDC motors have numerous advantages over regular DC motors but they have one big disadvantage, the complexity of control. Even though it has become relatively easy to design and manufacture PCBs and create our own hardware solutions for driving BLDC motors the proper low-cost solutions are yet to come. One of the reasons for this is the apparent complexity of writing the BLDC driving algorithms, Field oriented control (FOC) being an example of one of the most efficient ones.

The solutions that can be found on-line are almost exclusively very specific for certain hardware configuration and the microcontroller architecture used.

@@ -12,38 +13,54 @@ Therefore this is an attempt to:

- 🎯 Demystify FOC algorithm and make a robust but simple Arduino library: [Arduino *SimpleFOClibrary*](https://docs.simplefoc.com/arduino_simplefoc_library_showcase)

- Support as many motor + sensor + driver + mcu combinations out there

- 🎯 Develop a modular FOC supporting BLDC driver boards:

+ - ***NEW*** 📢: *Minimalistic* BLDC driver (<3Amps) : [SimpleFOCMini ](https://github.com/simplefoc/SimpleFOCMini).

- *Low-power* gimbal driver (<5Amps) : [*Arduino Simple**FOC**Shield*](https://docs.simplefoc.com/arduino_simplefoc_shield_showcase).

- - ***NEW*** 📢: *Medium-power* BLDC driver (<30Amps): [Arduino SimpleFOCPowerShield ](https://github.com/simplefoc/Arduino-SimpleFOC-PowerShield).

+ - *Medium-power* BLDC driver (<30Amps): [Arduino SimpleFOCPowerShield ](https://github.com/simplefoc/Arduino-SimpleFOC-PowerShield).

- See also [@byDagor](https://github.com/byDagor)'s *fully-integrated* ESP32 based board: [Dagor Brushless Controller](https://github.com/byDagor/Dagor-Brushless-Controller)

+

- NEW RELEASE 📢: SimpleFOClibrary v2.2 - see release

+ NEW RELEASE 📢: SimpleFOClibrary v2.2.2 see release

- - Sensor floating point error bugfix (initial solution) #83, #37

- - Sensor class restructuring - slight API change - docs

- - Restructured the generic code and simplified adding new mcus: IMPORTANT: an additional compiler flag needed for PlatformIO see issue and PlatformIO docs

- - Removed initial jump #110, #111

- - Double to float transformation of the code - performance increase by @sDessens (#100), @KaSroka (#100)

- - Docs webiste translated to Chinese! 🎉: Awesome work 😃 by @MINQING1101, @Deng-ge-open-source and @mingggggggg

- - New MCU support - docs

-

- - Support for arduino leonardo #108

- - Initial support for portenta h7 board in collaboration with

Arduino

Arduino

- - Initial support for esp8266

-

-

- - Low side current sensing initial support - docs

-

- - Initial support for stm32 B_G431B_ESC1 by @sDessens: PR #73

- - Initial support for samd21 by @maxlem: PR #79

- - Initial support for esp32 by @byDagor

-

-

+ - GenericCurrentSense bugfix and testing

+ - bugfix leonardo #170

+ - bugfix - no index search after specifying natural direction

+ - Low level API restructuring

+

+ - Driver API

+ - Current sense API

+

+

+ - New debugging interface - see in docs

+

+ - Static class SimpleFOCDebug

+

+

+ - CurrentSense API change - added method

linkDriver() - see in docs

+ - Low-side current sensing - see in docs

+

+ - ESP32 generic support for multiple motors

+ - Added low-side current sensing support for stm32 - only one motor

+

+ - f1 family

+ - f4 family

+ - g4 family

+

+

+

+

+ - New appraoch for current estimation for torque control using voltage - see in docs

+

+ - Support for motor KV rating - back emf estimation

+ - Using motor phase resistance

+

+

+ - KV rating and phase resistance used for open-loop current limiting as well - see in docs

-## Arduino *SimpleFOClibrary* v2.1

+## Arduino *SimpleFOClibrary* v2.2

@@ -53,58 +70,43 @@ Therefore this is an attempt to:

This video demonstrates the *Simple**FOC**library* basic usage, electronic connections and shows its capabilities.

-

### Features

-- **Arduino compatible**:

- - Arduino library code

- - Arduino Library Manager integration

+- **Easy install**:

+ - Arduino IDE: Arduino Library Manager integration

+ - PlatformIO

- **Open-Source**: Full code and documentation available on github

+- **Goal**:

+ - Support as many [sensor](https://docs.simplefoc.com/position_sensors) + [motor](https://docs.simplefoc.com/motors) + [driver](https://docs.simplefoc.com/drivers) + [current sense](https://docs.simplefoc.com/current_sense) combination as possible.

+ - Provide the up-to-date and in-depth documentation with API references and the examples

- **Easy to setup and configure**:

- - Easy hardware configuration

- - Easy [tuning the control loops](https://docs.simplefoc.com/motion_control)

-- **Modular**:

- - Supports as many [sensors, BLDC motors and driver boards](https://docs.simplefoc.com/supported_hardware) as possible

- - Supports multiple [MCU architectures](https://docs.simplefoc.com/microcontrollers):

- - Arduino: UNO, MEGA, any board with ATMega328 chips

- - STM32 boards: [Nucleo](https://www.st.com/en/evaluation-tools/stm32-nucleo-boards.html), [Bluepill](https://stm32-base.org/boards/STM32F103C8T6-Blue-Pill.html) ...

- - ESP32

- - Teensy boards

-- **Plug & play**: Arduino SimpleFOCShield

+ - Easy hardware configuration

+ - Each hardware component is a C++ object (easy to understand)

+ - Easy [tuning the control loops](https://docs.simplefoc.com/motion_control)

+ - [*Simple**FOC**Studio*](https://docs.simplefoc.com/studio) configuration GUI tool

+ - Built-in communication and monitoring

+- **Cross-platform**:

+ - Seamless code transfer from one microcontroller family to another

+ - Supports multiple [MCU architectures](https://docs.simplefoc.com/microcontrollers):

+ - Arduino: UNO, MEGA, DUE, Leonardo ....

+ - STM32

+ - ESP32

+ - Teensy

+ - many more ...

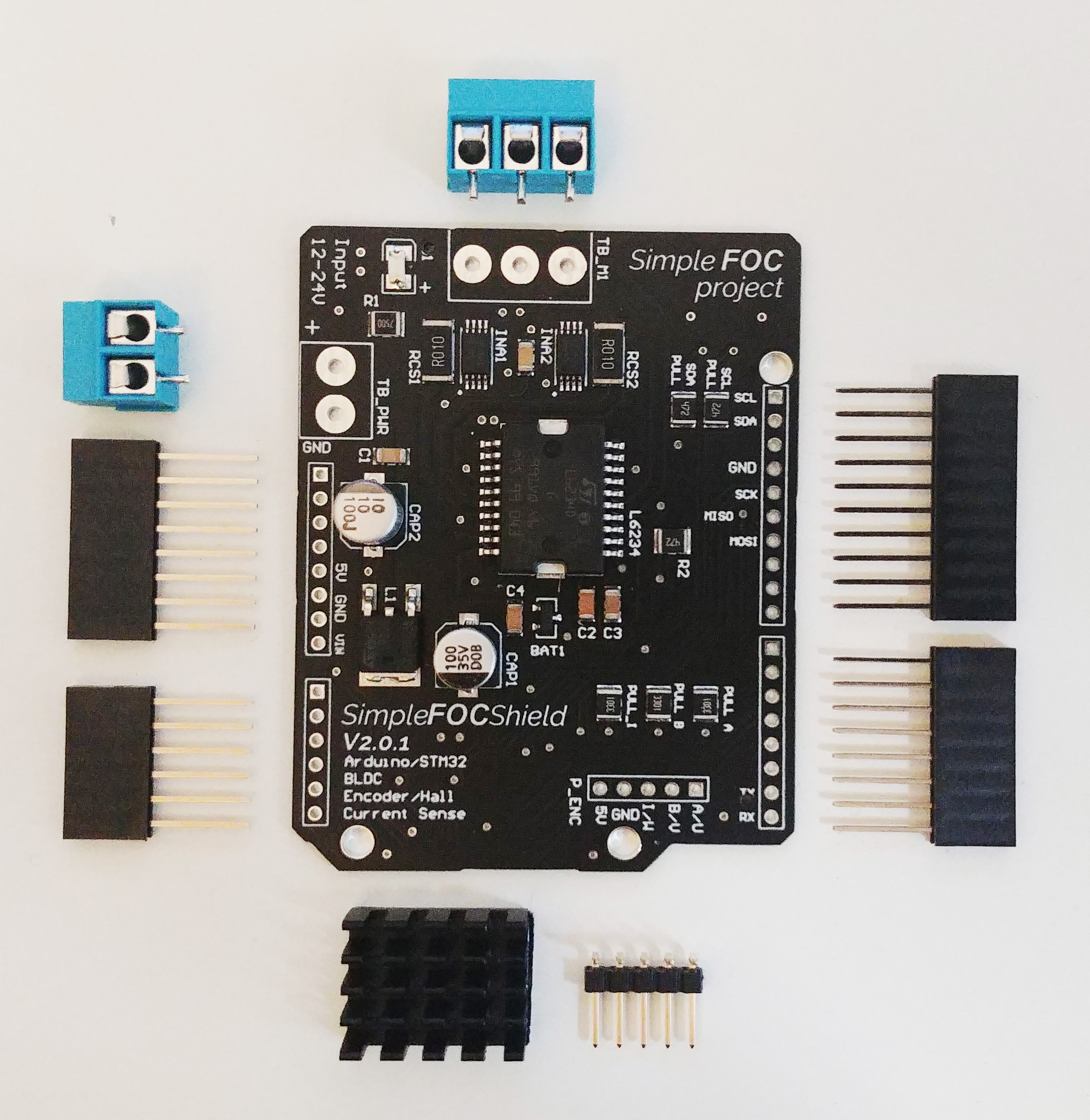

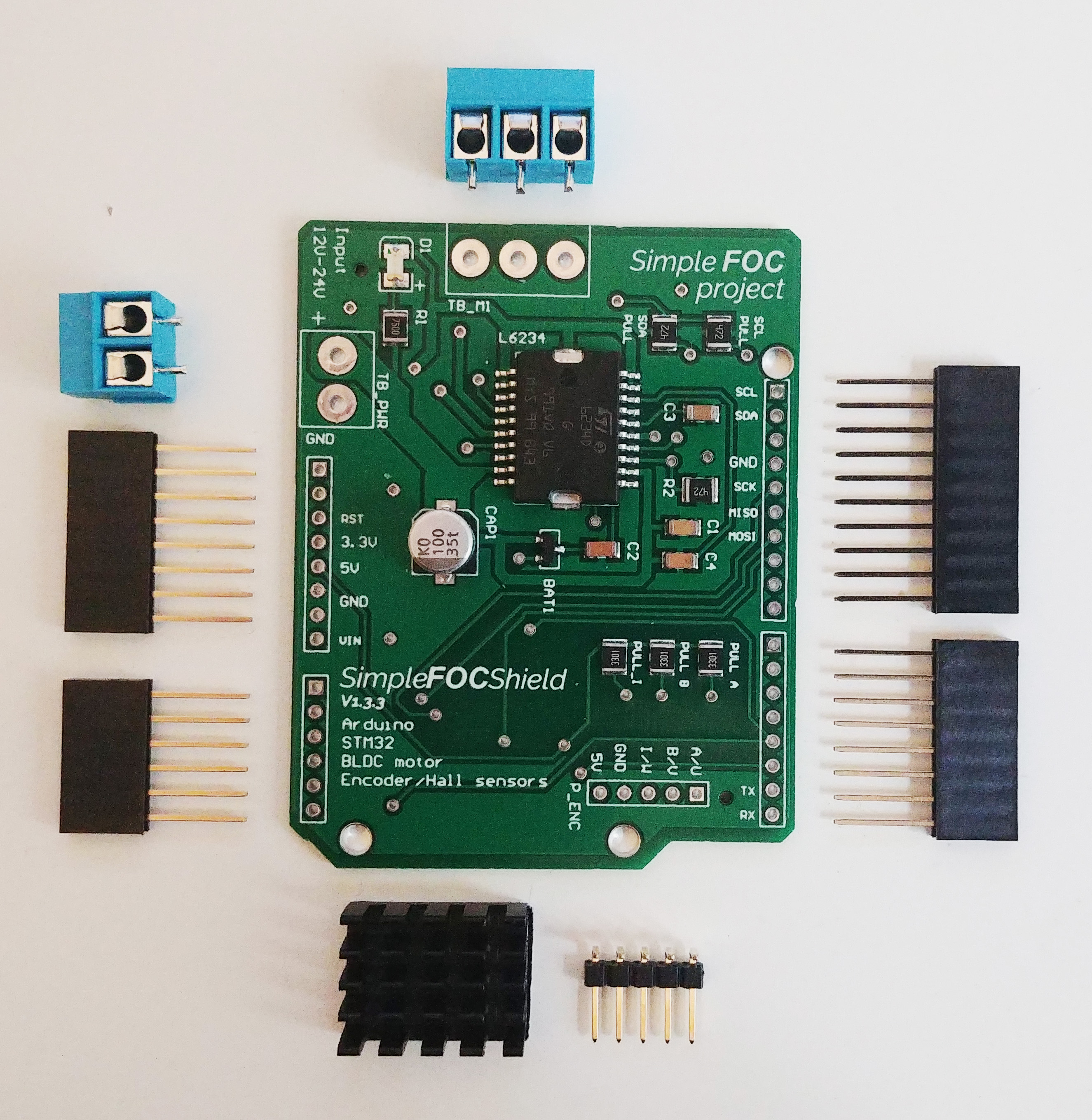

-## Arduino *SimpleFOCShield* v2.0.3

-

-

- -

-

-

-

-

-### Features

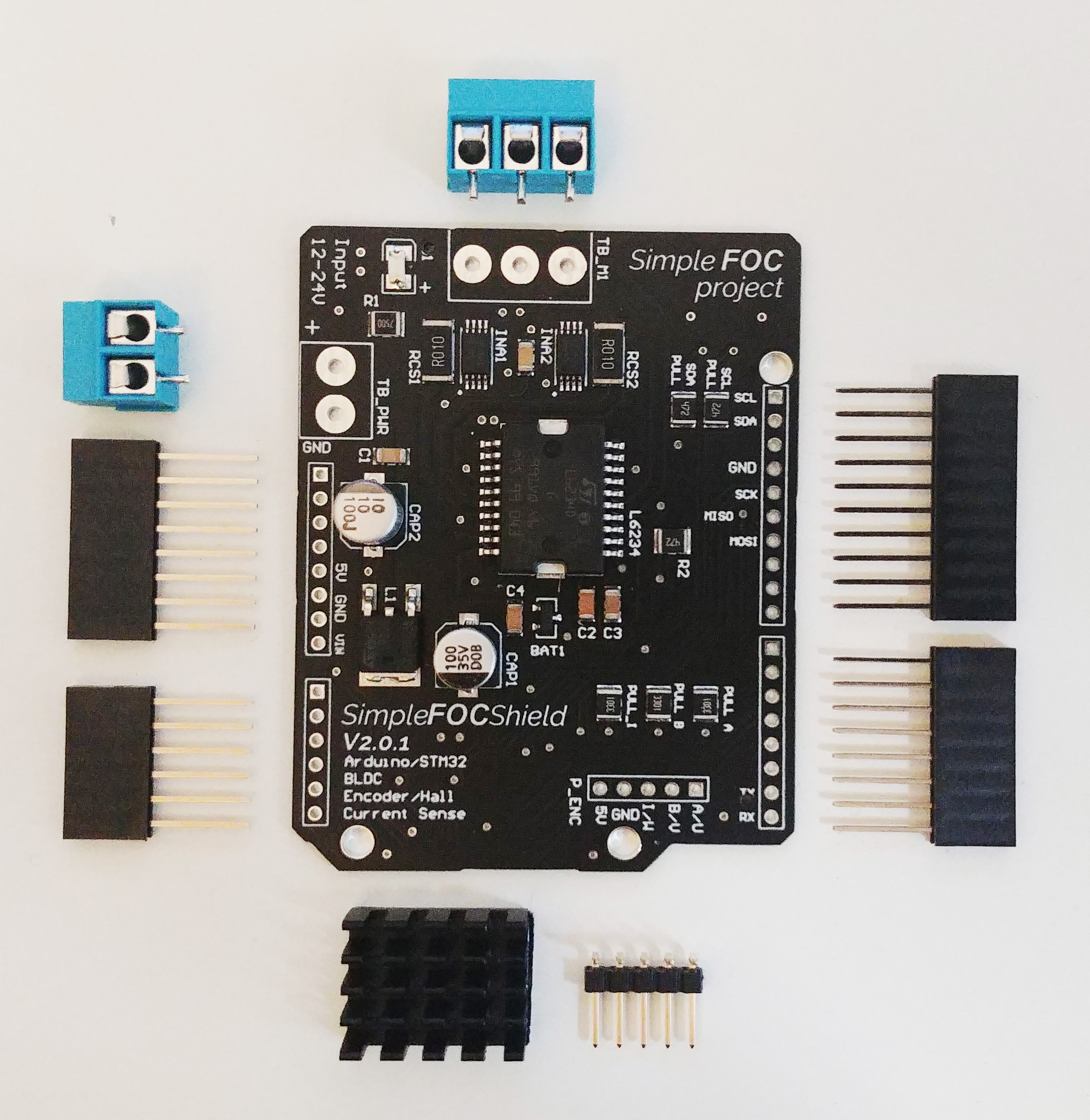

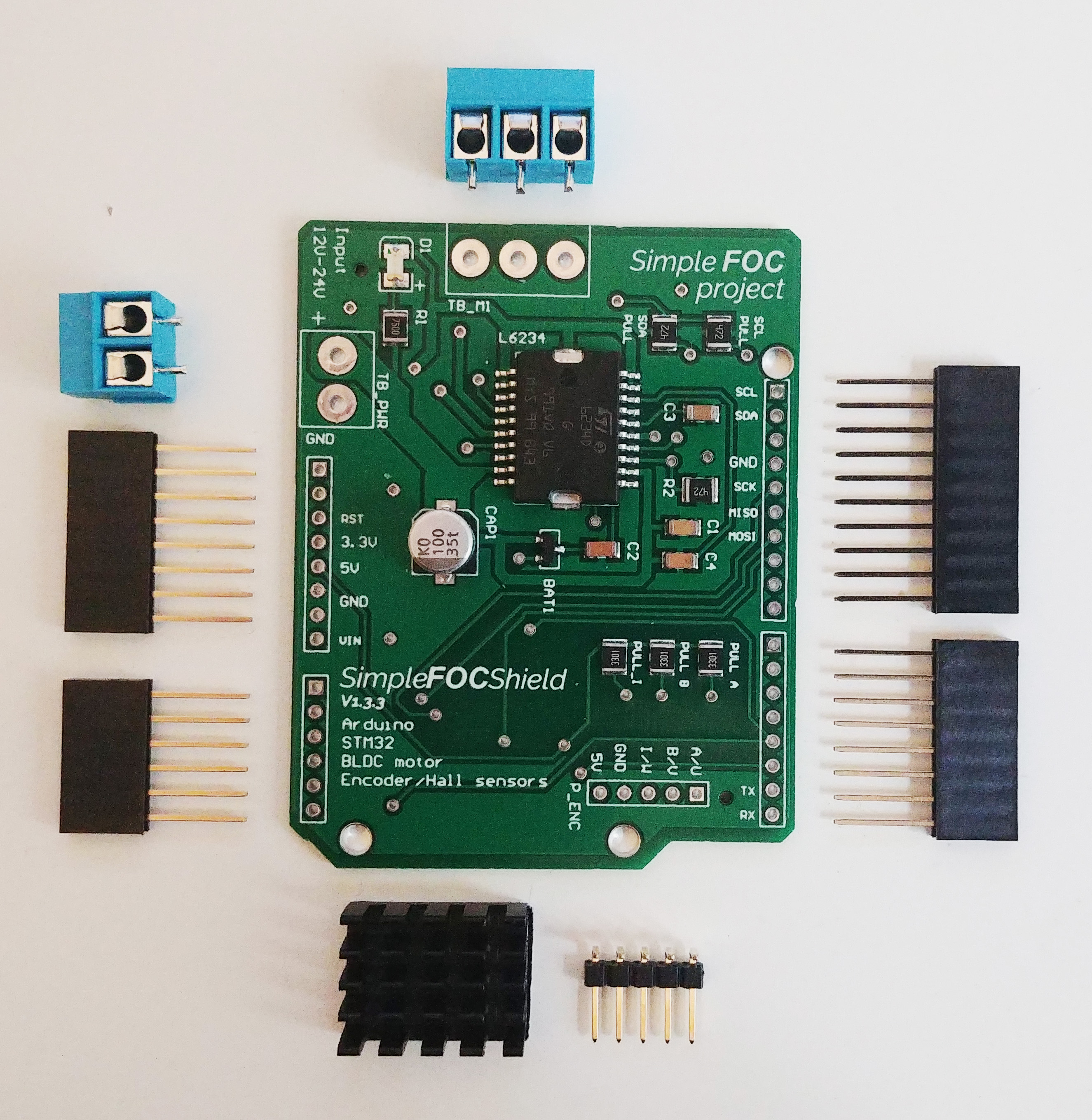

-- **Plug & play**: In combination with Arduino *Simple**FOC**library* - [github](https://github.com/simplefoc/Arduino-FOC)

-- **Low-cost**: Price of €15 - [Check the pricing](https://www.simplefoc.com/shop)

-- **In-line current sensing**: Up to 3Amps/5Amps bidirectional

- - configurable: 3.3Amps - 3.3V adc, 5Amps - 5V adc

-- **Integrated 8V regulator**:

- - Enable/disable by soldering pads

-- **Max power 120W** - max current 5A, power-supply 12-24V

- - Designed for Gimbal motors with the internal resistance >10 Ωs.

-- **Stackable**: running 2 motors in the same time

-- **Encoder/Hall sensors interface**: Integrated 3.3kΩ pullups (configurable)

-- **I2C interface**: Integrated 4.7kΩ pullups (configurable)

-- **Configurable pinout**: Hardware configuration - soldering connections

-- **Arduino headers**: Arduino UNO, Arduino MEGA, STM32 Nucleo boards...

-- **Open Source**: Fully available fabrication files - [how to make it yourself](https://docs.simplefoc.com/arduino_simplefoc_shield_fabrication)

-

+## Documentation

+Full API code documentation as well as example projects and step by step guides can be found on our [docs website](https://docs.simplefoc.com/).

+

## Getting Started

Depending on if you want to use this library as the plug and play Arduino library or you want to get insight in the algorithm and make changes there are two ways to install this code.

- Full library installation [Docs](https://docs.simplefoc.com/library_download)

-- Minimal project builder [Docs](https://docs.simplefoc.com/minimal_download)

+- PlatformIO [Docs](https://docs.simplefoc.com/library_platformio)

### Arduino *SimpleFOClibrary* installation to Arduino IDE

#### Arduino Library Manager

@@ -127,14 +129,19 @@ git clone https://github.com/simplefoc/Arduino-FOC.git

```

- Reopen Arduino IDE and you should have the library examples in `File > Examples > Simple FOC`.

-### *SimpleFOClibrary* minimal project builder

+## Community and contributing

+

+For all the questions regarding the potential implementation, applications, supported hardware and similar please visit our [community forum](https://community.simplefoc.com) or our [discord server](https://discord.gg/kWBwuzY32n).

+

+It is always helpful to hear the stories/problems/suggestions of people implementing the code and you might find a lot of answered questions there already!

+

+### Github Issues & Pull requests

-For those willing to experiment and to modify the code I suggest using the minimal project builder [minimal branch](https://github.com/simplefoc/Arduino-FOC/tree/minimal).

- > This code is completely independent and you can run it as any other Arduino Sketch without the need for any libraries.

+Please do not hesitate to leave an issue if you have problems/advices/suggestions regarding the code!

-All you need to do is:

-- Go to [minimal branch](https://github.com/simplefoc/Arduino-FOC/tree/minimal)

-- Follow the tutorial in the README file and choose only the library files that are necessary for your application.

+Pull requests are welcome, but let's first discuss them in [community forum](https://community.simplefoc.com)!

+

+If you'd like to contribute to this porject but you are not very familiar with github, don't worry, let us know either by posting at the community forum , by posting a github issue or at our discord server.

## Arduino code example

This is a simple Arduino code example implementing the velocity control program of a BLDC motor with encoder.

@@ -208,9 +215,6 @@ Here are some of the *Simple**FOC**library* and *Simple**FOC**Shield* applicatio

-## Documentation

-Find out more information about the Arduino SimpleFOC project in [docs website](https://docs.simplefoc.com/)

-

## Arduino FOC repo structure

Branch | Description | Status

diff --git a/examples/hardware_specific_examples/B_G431B_ESC1/B_G431B_ESC1.ino b/examples/hardware_specific_examples/B_G431B_ESC1/B_G431B_ESC1.ino

index 83451aa7..b6d6b8eb 100644

--- a/examples/hardware_specific_examples/B_G431B_ESC1/B_G431B_ESC1.ino

+++ b/examples/hardware_specific_examples/B_G431B_ESC1/B_G431B_ESC1.ino

@@ -6,12 +6,12 @@

// Motor instance

BLDCMotor motor = BLDCMotor(11);

-BLDCDriver6PWM driver = BLDCDriver6PWM(PHASE_UH, PHASE_UL, PHASE_VH, PHASE_VL, PHASE_WH, PHASE_WL);

-LowsideCurrentSense currentSense = LowsideCurrentSense(0.003, -64.0/7.0, OP1_OUT, OP2_OUT, OP3_OUT);

+BLDCDriver6PWM driver = BLDCDriver6PWM(A_PHASE_UH, A_PHASE_UL, A_PHASE_VH, A_PHASE_VL, A_PHASE_WH, A_PHASE_WL);

+LowsideCurrentSense currentSense = LowsideCurrentSense(0.003, -64.0/7.0, A_OP1_OUT, A_OP2_OUT, A_OP3_OUT);

// encoder instance

-Encoder encoder = Encoder(HALL2, HALL3, 2048, HALL1);

+Encoder encoder = Encoder(A_HALL2, A_HALL3, 2048, A_HALL1);

// Interrupt routine intialisation

// channel A and B callbacks

@@ -19,11 +19,9 @@ void doA(){encoder.handleA();}

void doB(){encoder.handleB();}

void doIndex(){encoder.handleIndex();}

-// angle set point variable

-float target_angle = 0;

// instantiate the commander

Commander command = Commander(Serial);

-void doTarget(char* cmd) { command.scalar(&target_angle, cmd); }

+void doTarget(char* cmd) { command.motion(&motor, cmd); }

void setup() {

@@ -40,6 +38,8 @@ void setup() {

driver.init();

// link the motor and the driver

motor.linkDriver(&driver);

+ // link current sense and the driver

+ currentSense.linkDriver(&driver);

// current sensing

currentSense.init();

@@ -94,14 +94,11 @@ void setup() {

_delay(1000);

}

-// angle set point variable

-float target_angle = 0;

-

void loop() {

// main FOC algorithm function

// Motion control function

- motor.move(target_angle);

+ motor.move();

// function intended to be used with serial plotter to monitor motor variables

// significantly slowing the execution down!!!!

diff --git a/examples/hardware_specific_examples/DRV8302_driver/esp32_current_control_low_side/esp32_current_control_low_side.ino b/examples/hardware_specific_examples/DRV8302_driver/esp32_current_control_low_side/esp32_current_control_low_side.ino

index 202aa337..84033b42 100644

--- a/examples/hardware_specific_examples/DRV8302_driver/esp32_current_control_low_side/esp32_current_control_low_side.ino

+++ b/examples/hardware_specific_examples/DRV8302_driver/esp32_current_control_low_side/esp32_current_control_low_side.ino

@@ -79,6 +79,10 @@ void setup() {

driver.init();

// link the motor and the driver

motor.linkDriver(&driver);

+ // link current sense and the driver

+ cs.linkDriver(&driver);

+

+ // align voltage

motor.voltage_sensor_align = 0.5;

// control loop type and torque mode

@@ -124,7 +128,6 @@ void setup() {

motor.init();

cs.init();

- cs.driverSync(&driver);

// driver 8302 has inverted gains on all channels

cs.gain_a *=-1;

cs.gain_b *=-1;

diff --git a/examples/hardware_specific_examples/Odrive_examples/odrive_example_encoder/odrive_example_encoder.ino b/examples/hardware_specific_examples/Odrive_examples/odrive_example_encoder/odrive_example_encoder.ino

new file mode 100644

index 00000000..b89c215f

--- /dev/null

+++ b/examples/hardware_specific_examples/Odrive_examples/odrive_example_encoder/odrive_example_encoder.ino

@@ -0,0 +1,134 @@

+/*

+ Odrive robotics' hardware is one of the best BLDC motor foc supporting hardware out there.

+

+ This is an example code that can be directly uploaded to the Odrive using the SWD programmer.

+ This code uses an encoder with 500 cpr and a BLDC motor with 7 pole pairs connected to the M0 interface of the Odrive.

+

+ This is a short template code and the idea is that you are able to adapt to your needs not to be a complete solution. :D

+*/

+#include

+

+// Odrive M0 motor pinout

+#define M0_INH_A PA8

+#define M0_INH_B PA9

+#define M0_INH_C PA10

+#define M0_INL_A PB13

+#define M0_INL_B PB14

+#define M0_INL_C PB15

+// M0 currnets

+#define M0_IB PC0

+#define M0_IC PC1

+// Odrive M0 encoder pinout

+#define M0_ENC_A PB4

+#define M0_ENC_B PB5

+#define M0_ENC_Z PC9

+

+

+// Odrive M1 motor pinout

+#define M1_INH_A PC6

+#define M1_INH_B PC7

+#define M1_INH_C PC8

+#define M1_INL_A PA7

+#define M1_INL_B PB0

+#define M1_INL_C PB1

+// M0 currnets

+#define M1_IB PC2

+#define M1_IC PC3

+// Odrive M1 encoder pinout

+#define M1_ENC_A PB6

+#define M1_ENC_B PB7

+#define M1_ENC_Z PC15

+

+// M1 & M2 common enable pin

+#define EN_GATE PB12

+

+// SPI pinout

+#define SPI3_SCL PC10

+#define SPI3_MISO PC11

+#define SPI3_MOSO PC12

+

+// Motor instance

+BLDCMotor motor = BLDCMotor(7);

+BLDCDriver6PWM driver = BLDCDriver6PWM(M0_INH_A,M0_INL_A, M0_INH_B,M0_INL_B, M0_INH_C,M0_INL_C, EN_GATE);

+

+// instantiate the commander

+Commander command = Commander(Serial);

+void doMotor(char* cmd) { command.motor(&motor, cmd); }

+

+// low side current sensing define

+// 0.0005 Ohm resistor

+// gain of 10x

+// current sensing on B and C phases, phase A not connected

+LowsideCurrentSense current_sense = LowsideCurrentSense(0.0005f, 10.0f, _NC, M0_IB, M0_IC);

+

+Encoder encoder = Encoder(M0_ENC_A, M0_ENC_B, 500,M0_ENC_Z);

+// Interrupt routine intialisation

+// channel A and B callbacks

+void doA(){encoder.handleA();}

+void doB(){encoder.handleB();}

+void doI(){encoder.handleIndex();}

+

+void setup(){

+

+ // pwm frequency to be used [Hz]

+ driver.pwm_frequency = 20000;

+ // power supply voltage [V]

+ driver.voltage_power_supply = 20;

+ // Max DC voltage allowed - default voltage_power_supply

+ driver.voltage_limit = 20;

+ // driver init

+ driver.init();

+ // link the motor and the driver

+ motor.linkDriver(&driver);

+

+ // initialize encoder sensor hardware

+ encoder.init();

+ encoder.enableInterrupts(doA, doB, doI);

+ // link the motor to the sensor

+ motor.linkSensor(&encoder);

+

+ // control loop type and torque mode

+ motor.torque_controller = TorqueControlType::voltage;

+ motor.controller = MotionControlType::torque;

+

+ // max voltage allowed for motion control

+ motor.voltage_limit = 8.0;

+ // alignment voltage limit

+ motor.voltage_sensor_align = 0.5;

+

+

+ Serial.begin(115200);

+ // comment out if not needed

+ motor.useMonitoring(Serial);

+ motor.monitor_variables = _MON_CURR_Q | _MON_CURR_D;

+ motor.monitor_downsample = 1000;

+

+ // add target command T

+ command.add('M', doMotor, "motor M0");

+

+ // initialise motor

+ motor.init();

+

+ // link the driver

+ current_sense.linkDriver(&driver);

+ // init the current sense

+ current_sense.init();

+ current_sense.skip_align = true;

+ motor.linkCurrentSense(¤t_sense);

+

+ // init FOC

+ motor.initFOC();

+ delay(1000);

+}

+

+void loop(){

+

+ // foc loop

+ motor.loopFOC();

+ // motion control

+ motor.move();

+ // monitoring

+ motor.monitor();

+ // user communication

+ command.run();

+}

\ No newline at end of file

diff --git a/examples/hardware_specific_examples/Odrive_examples/odrive_example_spi/odrive_example_spi.ino b/examples/hardware_specific_examples/Odrive_examples/odrive_example_spi/odrive_example_spi.ino

new file mode 100644

index 00000000..2aed6bfb

--- /dev/null

+++ b/examples/hardware_specific_examples/Odrive_examples/odrive_example_spi/odrive_example_spi.ino

@@ -0,0 +1,132 @@

+/*

+ Odrive robotics' hardware is one of the best BLDC motor foc supporting hardware out there.

+

+ This is an example code that can be directly uploaded to the Odrive using the SWD programmer.

+ This code uses an magnetic spi sensor AS5047 and a BLDC motor with 11 pole pairs connected to the M0 interface of the Odrive.

+

+ This is a short template code and the idea is that you are able to adapt to your needs not to be a complete solution. :D

+*/

+#include

+

+// Odrive M0 motor pinout

+#define M0_INH_A PA8

+#define M0_INH_B PA9

+#define M0_INH_C PA10

+#define M0_INL_A PB13

+#define M0_INL_B PB14

+#define M0_INL_C PB15

+// M0 currnets

+#define M0_IB PC0

+#define M0_IC PC1

+// Odrive M0 encoder pinout

+#define M0_ENC_A PB4

+#define M0_ENC_B PB5

+#define M0_ENC_Z PC9

+

+

+// Odrive M1 motor pinout

+#define M1_INH_A PC6

+#define M1_INH_B PC7

+#define M1_INH_C PC8

+#define M1_INL_A PA7

+#define M1_INL_B PB0

+#define M1_INL_C PB1

+// M0 currnets

+#define M1_IB PC2

+#define M1_IC PC3

+// Odrive M1 encoder pinout

+#define M1_ENC_A PB6

+#define M1_ENC_B PB7

+#define M1_ENC_Z PC15

+

+// M1 & M2 common enable pin

+#define EN_GATE PB12

+

+// SPI pinout

+#define SPI3_SCL PC10

+#define SPI3_MISO PC11

+#define SPI3_MOSO PC12

+

+// Motor instance

+BLDCMotor motor = BLDCMotor(11);

+BLDCDriver6PWM driver = BLDCDriver6PWM(M0_INH_A,M0_INL_A, M0_INH_B,M0_INL_B, M0_INH_C,M0_INL_C, EN_GATE);

+

+// instantiate the commander

+Commander command = Commander(Serial);

+void doMotor(char* cmd) { command.motor(&motor, cmd); }

+

+// low side current sensing define

+// 0.0005 Ohm resistor

+// gain of 10x

+// current sensing on B and C phases, phase A not connected

+LowsideCurrentSense current_sense = LowsideCurrentSense(0.0005f, 10.0f, _NC, M0_IB, M0_IC);

+

+// MagneticSensorSPI(int cs, float _cpr, int _angle_register)

+// config - SPI config

+// cs - SPI chip select pin

+MagneticSensorSPI sensor = MagneticSensorSPI(AS5147_SPI, M0_ENC_A);

+SPIClass SPI_3(SPI3_MOSO, SPI3_MISO, SPI3_SCL);

+

+void setup(){

+

+ // pwm frequency to be used [Hz]

+ driver.pwm_frequency = 20000;

+ // power supply voltage [V]

+ driver.voltage_power_supply = 20;

+ // Max DC voltage allowed - default voltage_power_supply

+ driver.voltage_limit = 20;

+ // driver init

+ driver.init();

+ // link the motor and the driver

+ motor.linkDriver(&driver);

+

+ // initialise magnetic sensor hardware

+ sensor.init(&SPI_3);

+ // link the motor to the sensor

+ motor.linkSensor(&sensor);

+

+ // control loop type and torque mode

+ motor.torque_controller = TorqueControlType::voltage;

+ motor.controller = MotionControlType::torque;

+

+ // max voltage allowed for motion control

+ motor.voltage_limit = 8.0;

+ // alignment voltage limit

+ motor.voltage_sensor_align = 0.5;

+

+

+ Serial.begin(115200);

+ // comment out if not needed

+ motor.useMonitoring(Serial);

+ motor.monitor_variables = _MON_CURR_Q | _MON_CURR_D;

+ motor.monitor_downsample = 1000;

+

+ // add target command T

+ command.add('M', doMotor, "motor M0");

+

+ // initialise motor

+ motor.init();

+

+ // link the driver

+ current_sense.linkDriver(&driver);

+ // init the current sense

+ current_sense.init();

+ current_sense.skip_align = true;

+ motor.linkCurrentSense(¤t_sense);

+

+ // init FOC

+ motor.initFOC();

+ delay(1000);

+}

+

+void loop(){

+

+ // foc loop

+ motor.loopFOC();

+ // motion control

+ motor.move();

+ // monitoring

+ motor.monitor();

+ // user communication

+ command.run();

+}

\ No newline at end of file

diff --git a/examples/hardware_specific_examples/SimpleFOC-PowerShield/version_v02/single_full_control_example/single_full_control_example.ino b/examples/hardware_specific_examples/SimpleFOC-PowerShield/version_v02/single_full_control_example/single_full_control_example.ino

index dfad6e3a..a508bb19 100644

--- a/examples/hardware_specific_examples/SimpleFOC-PowerShield/version_v02/single_full_control_example/single_full_control_example.ino

+++ b/examples/hardware_specific_examples/SimpleFOC-PowerShield/version_v02/single_full_control_example/single_full_control_example.ino

@@ -33,6 +33,8 @@ void setup() {

driver.init();

// link driver

motor.linkDriver(&driver);

+ // link current sense and the driver

+ current_sense.linkDriver(&driver);

motor.voltage_sensor_align = 1;

// set control loop type to be used

diff --git a/examples/hardware_specific_examples/SimpleFOCMini/angle_control/angle_control.ino b/examples/hardware_specific_examples/SimpleFOCMini/angle_control/angle_control.ino

new file mode 100644

index 00000000..9102c89a

--- /dev/null

+++ b/examples/hardware_specific_examples/SimpleFOCMini/angle_control/angle_control.ino

@@ -0,0 +1,125 @@

+/**

+ *

+ * SimpleFOCMini motor control example

+ *

+ * For Arduino UNO, the most convenient way to use the board is to stack it to the pins:

+ * - 12 - GND

+ * - 11 - IN1

+ * - 10 - IN2

+ * - 9 - IN3

+ * - 8 - EN

+ *

+ * For other boards with UNO headers but more PWM channles such as esp32, nucleo-64, samd51 metro etc, the best way to most convenient pinout is:

+ * - GND - GND

+ * - 13 - IN1

+ * - 12 - IN2

+ * - 11 - IN3

+ * - 9 - EN

+ *

+ * For the boards without arduino uno headers, the choice of pinout is a lot less constrained.

+ *

+ */

+#include

+

+

+// BLDC motor & driver instance

+BLDCMotor motor = BLDCMotor(11);

+BLDCDriver3PWM driver = BLDCDriver3PWM(11, 10, 9, 8);

+

+// encoder instance

+Encoder encoder = Encoder(2, 3, 500);

+// Interrupt routine intialisation

+// channel A and B callbacks

+void doA(){encoder.handleA();}

+void doB(){encoder.handleB();}

+

+// instantiate the commander

+Commander command = Commander(Serial);

+void doMotor(char* cmd) { command.motor(&motor, cmd); }

+

+void setup() {

+ // if SimpleFOCMini is stacked in arduino headers

+ // on pins 12,11,10,9,8

+ // pin 12 is used as ground

+ pinMode(12,OUTPUT);

+ pinMode(12,LOW);

+

+ // initialize encoder sensor hardware

+ encoder.init();

+ encoder.enableInterrupts(doA, doB);

+ // link the motor to the sensor

+ motor.linkSensor(&encoder);

+

+ // driver config

+ // power supply voltage [V]

+ driver.voltage_power_supply = 12;

+ driver.init();

+ // link the motor and the driver

+ motor.linkDriver(&driver);

+

+ // aligning voltage [V]

+ motor.voltage_sensor_align = 3;

+

+ // set motion control loop to be used

+ motor.controller = MotionControlType::angle;

+

+ // contoller configuration

+ // default parameters in defaults.h

+

+ // velocity PI controller parameters

+ motor.PID_velocity.P = 0.2f;

+ motor.PID_velocity.I = 20;

+ motor.PID_velocity.D = 0;

+ // default voltage_power_supply

+ motor.voltage_limit = 6;

+ // jerk control using voltage voltage ramp

+ // default value is 300 volts per sec ~ 0.3V per millisecond

+ motor.PID_velocity.output_ramp = 1000;

+

+ // velocity low pass filtering time constant

+ motor.LPF_velocity.Tf = 0.01f;

+

+ // angle P controller

+ motor.P_angle.P = 20;

+ // maximal velocity of the position control

+ motor.velocity_limit = 4;

+

+

+ // use monitoring with serial

+ Serial.begin(115200);

+ // comment out if not needed

+ motor.useMonitoring(Serial);

+

+ // initialize motor

+ motor.init();

+ // align encoder and start FOC

+ motor.initFOC();

+

+ // add target command M

+ command.add('M', doMotor, "motor");

+

+ Serial.println(F("Motor ready."));

+ Serial.println(F("Set the target angle using serial terminal:"));

+ _delay(1000);

+}

+

+void loop() {

+ // main FOC algorithm function

+ // the faster you run this function the better

+ // Arduino UNO loop ~1kHz

+ // Bluepill loop ~10kHz

+ motor.loopFOC();

+

+ // Motion control function

+ // velocity, position or voltage (defined in motor.controller)

+ // this function can be run at much lower frequency than loopFOC() function

+ // You can also use motor.move() and set the motor.target in the code

+ motor.move();

+

+ // function intended to be used with serial plotter to monitor motor variables

+ // significantly slowing the execution down!!!!

+ // motor.monitor();

+

+ // user communication

+ command.run();

+}

\ No newline at end of file

diff --git a/examples/hardware_specific_examples/SimpleFOCShield/version_v2/double_full_control_example/double_full_control_example.ino b/examples/hardware_specific_examples/SimpleFOCShield/version_v2/double_full_control_example/double_full_control_example.ino

index 259b23ee..2d28790c 100644

--- a/examples/hardware_specific_examples/SimpleFOCShield/version_v2/double_full_control_example/double_full_control_example.ino

+++ b/examples/hardware_specific_examples/SimpleFOCShield/version_v2/double_full_control_example/double_full_control_example.ino

@@ -56,11 +56,16 @@ void setup() {

driver1.init();

// link driver

motor1.linkDriver(&driver1);

+ // link current sense and the driver

+ current_sense1.linkDriver(&driver1);

+

// power supply voltage [V]

driver2.voltage_power_supply = 12;

driver2.init();

// link driver

motor2.linkDriver(&driver2);

+ // link current sense and the driver

+ current_sense2.linkDriver(&driver2);

// set control loop type to be used

motor1.controller = MotionControlType::torque;

diff --git a/examples/hardware_specific_examples/SimpleFOCShield/version_v2/single_full_control_example/single_full_control_example.ino b/examples/hardware_specific_examples/SimpleFOCShield/version_v2/single_full_control_example/single_full_control_example.ino

index 2d6c3ca6..688c8b6a 100644

--- a/examples/hardware_specific_examples/SimpleFOCShield/version_v2/single_full_control_example/single_full_control_example.ino

+++ b/examples/hardware_specific_examples/SimpleFOCShield/version_v2/single_full_control_example/single_full_control_example.ino

@@ -17,7 +17,7 @@ InlineCurrentSense current_sense = InlineCurrentSense(0.01, 50.0, A0, A2);

// commander communication instance

Commander command = Commander(Serial);

-void doTarget(char* cmd){ command.scalar(&motor.target, cmd); }

+void doMotion(char* cmd){ command.motion(&motor, cmd); }

// void doMotor(char* cmd){ command.motor(&motor, cmd); }

void setup() {

@@ -34,6 +34,8 @@ void setup() {

driver.init();

// link driver

motor.linkDriver(&driver);

+ // link current sense and the driver

+ current_sense.linkDriver(&driver);

// set control loop type to be used

motor.controller = MotionControlType::torque;

@@ -74,7 +76,7 @@ void setup() {

motor.target = 2;

// subscribe motor to the commander

- command.add('T', doTarget, "target");

+ command.add('T', doMotion, "motion control");

// command.add('M', doMotor, "motor");

// Run user commands to configure and the motor (find the full command list in docs.simplefoc.com)

diff --git a/examples/motion_control/open_loop_motor_control/open_loop_position_example/open_loop_position_example.ino b/examples/motion_control/open_loop_motor_control/open_loop_position_example/open_loop_position_example.ino

index a4756352..83b1fb32 100644

--- a/examples/motion_control/open_loop_motor_control/open_loop_position_example/open_loop_position_example.ino

+++ b/examples/motion_control/open_loop_motor_control/open_loop_position_example/open_loop_position_example.ino

@@ -18,18 +18,29 @@ float target_position = 0;

// instantiate the commander

Commander command = Commander(Serial);

void doTarget(char* cmd) { command.scalar(&target_position, cmd); }

+void doLimit(char* cmd) { command.scalar(&motor.voltage_limit, cmd); }

+void doVelocity(char* cmd) { command.scalar(&motor.velocity_limit, cmd); }

void setup() {

// driver config

// power supply voltage [V]

driver.voltage_power_supply = 12;

+ // limit the maximal dc voltage the driver can set

+ // as a protection measure for the low-resistance motors

+ // this value is fixed on startup

+ driver.voltage_limit = 6;

driver.init();

// link the motor and the driver

motor.linkDriver(&driver);

// limiting motor movements

+ // limit the voltage to be set to the motor

+ // start very low for high resistance motors

+ // currnet = resistance*voltage, so try to be well under 1Amp

motor.voltage_limit = 3; // [V]

+ // limit/set the velocity of the transition in between

+ // target angles

motor.velocity_limit = 5; // [rad/s] cca 50rpm

// open loop control config

motor.controller = MotionControlType::angle_openloop;

@@ -39,6 +50,8 @@ void setup() {

// add target command T

command.add('T', doTarget, "target angle");

+ command.add('L', doLimit, "voltage limit");

+ command.add('V', doLimit, "movement velocity");

Serial.begin(115200);

Serial.println("Motor ready!");

diff --git a/examples/motion_control/open_loop_motor_control/open_loop_velocity_example/open_loop_velocity_example.ino b/examples/motion_control/open_loop_motor_control/open_loop_velocity_example/open_loop_velocity_example.ino

index f7a82eb3..7a4a14ac 100644

--- a/examples/motion_control/open_loop_motor_control/open_loop_velocity_example/open_loop_velocity_example.ino

+++ b/examples/motion_control/open_loop_motor_control/open_loop_velocity_example/open_loop_velocity_example.ino

@@ -19,19 +19,26 @@ float target_velocity = 0;

// instantiate the commander

Commander command = Commander(Serial);

void doTarget(char* cmd) { command.scalar(&target_velocity, cmd); }

+void doLimit(char* cmd) { command.scalar(&motor.voltage_limit, cmd); }

void setup() {

// driver config

// power supply voltage [V]

driver.voltage_power_supply = 12;

+ // limit the maximal dc voltage the driver can set

+ // as a protection measure for the low-resistance motors

+ // this value is fixed on startup

+ driver.voltage_limit = 6;

driver.init();

// link the motor and the driver

motor.linkDriver(&driver);

// limiting motor movements

+ // limit the voltage to be set to the motor

+ // start very low for high resistance motors

+ // currnet = resistance*voltage, so try to be well under 1Amp

motor.voltage_limit = 3; // [V]

- motor.velocity_limit = 5; // [rad/s] cca 50rpm

// open loop control config

motor.controller = MotionControlType::velocity_openloop;

@@ -41,6 +48,7 @@ void setup() {

// add target command T

command.add('T', doTarget, "target velocity");

+ command.add('L', doLimit, "voltage limit");

Serial.begin(115200);

Serial.println("Motor ready!");

diff --git a/examples/motion_control/position_motion_control/encoder/angle_control/angle_control.ino b/examples/motion_control/position_motion_control/encoder/angle_control/angle_control.ino

index 942f73dc..ccb3980e 100644

--- a/examples/motion_control/position_motion_control/encoder/angle_control/angle_control.ino

+++ b/examples/motion_control/position_motion_control/encoder/angle_control/angle_control.ino

@@ -24,9 +24,6 @@

*

*/

#include

-// software interrupt library

-#include

-#include

// BLDC motor & driver instance

BLDCMotor motor = BLDCMotor(11);

@@ -36,15 +33,12 @@ BLDCDriver3PWM driver = BLDCDriver3PWM(9, 5, 6, 8);

//StepperDriver4PWM driver = StepperDriver4PWM(9, 5, 10, 6, 8);

// encoder instance

-Encoder encoder = Encoder(2, 3, 8192, A0);

+Encoder encoder = Encoder(2, 3, 8192);

// Interrupt routine intialisation

// channel A and B callbacks

void doA(){encoder.handleA();}

void doB(){encoder.handleB();}

-void doIndex(){encoder.handleIndex();}

-// If no available hadware interrupt pins use the software interrupt

-PciListenerImp listenerIndex(encoder.index_pin, doIndex);

// angle set point variable

float target_angle = 0;

@@ -57,8 +51,6 @@ void setup() {

// initialize encoder sensor hardware

encoder.init();

encoder.enableInterrupts(doA, doB);

- // software interrupts

- PciManager.registerListener(&listenerIndex);

// link the motor to the sensor

motor.linkSensor(&encoder);

@@ -71,8 +63,6 @@ void setup() {

// aligning voltage [V]

motor.voltage_sensor_align = 3;

- // index search velocity [rad/s]

- motor.velocity_index_search = 3;

// set motion control loop to be used

motor.controller = MotionControlType::angle;

diff --git a/examples/motion_control/torque_control/encoder/current_control/current_control.ino b/examples/motion_control/torque_control/encoder/current_control/current_control.ino

index 8b1ec96b..3f3ccb18 100644

--- a/examples/motion_control/torque_control/encoder/current_control/current_control.ino

+++ b/examples/motion_control/torque_control/encoder/current_control/current_control.ino

@@ -39,6 +39,8 @@ void setup() {

driver.init();

// link driver

motor.linkDriver(&driver);

+ // link current sense and the driver

+ current_sense.linkDriver(&driver);

// current sense init hardware

current_sense.init();

diff --git a/examples/utils/calibration/alignment_and_cogging_test/alignment_and_cogging_test.ino b/examples/utils/calibration/alignment_and_cogging_test/alignment_and_cogging_test.ino

index 3fcd7b30..7324edf0 100644

--- a/examples/utils/calibration/alignment_and_cogging_test/alignment_and_cogging_test.ino

+++ b/examples/utils/calibration/alignment_and_cogging_test/alignment_and_cogging_test.ino

@@ -35,9 +35,10 @@ void testAlignmentAndCogging(int direction) {

for (int i = 0; i < sample_count; i++) {

- float electricAngle = (float) direction * i * motor.pole_pairs * shaft_rotation / sample_count;

+ float shaftAngle = (float) direction * i * shaft_rotation / sample_count;

+ float electricAngle = (float) shaftAngle * motor.pole_pairs;

// move and wait

- motor.move(electricAngle * PI / 180);

+ motor.move(shaftAngle * PI / 180);

_delay(5);

// measure

diff --git a/examples/utils/calibration/find_kv_rating/encoder/find_kv_rating/find_kv_rating.ino b/examples/utils/calibration/find_kv_rating/encoder/find_kv_rating/find_kv_rating.ino

new file mode 100644

index 00000000..76fb46b0

--- /dev/null

+++ b/examples/utils/calibration/find_kv_rating/encoder/find_kv_rating/find_kv_rating.ino

@@ -0,0 +1,102 @@

+/**

+ *

+ * Find KV rating for motor with encoder

+ *

+ * Motor KV rating is defiend as the increase of the motor velocity expressed in rotations per minute [rpm] per each 1 Volt int voltage control mode.

+ *

+ * This example will set your motor in the torque control mode using voltage and set 1 volt to the motor. By reading the velocity it will calculat the motors KV rating.

+ * - To make this esimation more credible you can try increasing the target voltage (or decrease in some cases)

+ * - The KV rating should be realatively static number - it should not change considerably with the increase in the voltage

+ *

+ */

+#include

+

+

+// BLDC motor & driver instance

+BLDCMotor motor = BLDCMotor(11);

+BLDCDriver3PWM driver = BLDCDriver3PWM(9, 5, 6, 8);

+// Stepper motor & driver instance

+//StepperMotor motor = StepperMotor(50);

+//StepperDriver4PWM driver = StepperDriver4PWM(9, 5, 10, 6, 8);

+

+// encoder instance

+Encoder sensor = Encoder(2, 3, 8192);

+

+// Interrupt routine intialisation

+// channel A and B callbacks

+void doA(){sensor.handleA();}

+void doB(){sensor.handleB();}

+

+

+// voltage set point variable

+float target_voltage = 1;

+

+// instantiate the commander

+Commander command = Commander(Serial);

+void doTarget(char* cmd) { command.scalar(&target_voltage, cmd); }

+void calcKV(char* cmd) {

+ // calculate the KV

+ Serial.println(motor.shaft_velocity/motor.target*30.0f/_PI);

+

+}

+

+void setup() {

+

+ // initialize encoder sensor hardware

+ sensor.init();

+ sensor.enableInterrupts(doA, doB);

+ // link the motor to the sensor

+ motor.linkSensor(&sensor);

+

+ // driver config

+ // IMPORTANT!

+ // make sure to set the correct power supply voltage [V]

+ driver.voltage_power_supply = 12;

+ driver.init();

+ // link driver

+ motor.linkDriver(&driver);

+

+ // aligning voltage

+ motor.voltage_sensor_align = 3;

+

+ // set motion control loop to be used

+ motor.controller = MotionControlType::torque;

+

+ // use monitoring with serial

+ Serial.begin(115200);

+ // comment out if not needed

+ motor.useMonitoring(Serial);

+

+ // initialize motor

+ motor.init();

+ // align sensor and start FOC

+ motor.initFOC();

+

+ // add target command T

+ command.add('T', doTarget, "target voltage");

+ command.add('K', calcKV, "calculate KV rating");

+

+ Serial.println(F("Motor ready."));

+ Serial.println(F("Set the target voltage : - commnad T"));

+ Serial.println(F("Calculate the motor KV : - command K"));

+ _delay(1000);

+}

+

+

+void loop() {

+

+ // main FOC algorithm function

+ // the faster you run this function the better

+ // Arduino UNO loop ~1kHz

+ // Bluepill loop ~10kHz

+ motor.loopFOC();

+

+ // Motion control function

+ // velocity, position or voltage (defined in motor.controller)

+ // this function can be run at much lower frequency than loopFOC() function

+ // You can also use motor.move() and set the motor.target in the code

+ motor.move(target_voltage);

+

+ // user communication

+ command.run();

+}

\ No newline at end of file

diff --git a/examples/utils/calibration/find_kv_rating/hall_sensor/find_kv_rating/find_kv_rating.ino b/examples/utils/calibration/find_kv_rating/hall_sensor/find_kv_rating/find_kv_rating.ino

new file mode 100644

index 00000000..3abef467

--- /dev/null

+++ b/examples/utils/calibration/find_kv_rating/hall_sensor/find_kv_rating/find_kv_rating.ino

@@ -0,0 +1,99 @@

+/**

+ *

+ * Find KV rating for motor with Hall sensors

+ *

+ * Motor KV rating is defiend as the increase of the motor velocity expressed in rotations per minute [rpm] per each 1 Volt int voltage control mode.

+ *

+ * This example will set your motor in the torque control mode using voltage and set 1 volt to the motor. By reading the velocity it will calculat the motors KV rating.

+ * - To make this esimation more credible you can try increasing the target voltage (or decrease in some cases)

+ * - The KV rating should be realatively static number - it should not change considerably with the increase in the voltage

+ */

+#include

+

+

+// BLDC motor & driver instance

+BLDCMotor motor = BLDCMotor(11);

+BLDCDriver3PWM driver = BLDCDriver3PWM(9, 5, 6, 8);

+

+// hall sensor instance

+HallSensor sensor = HallSensor(2, 3, 4, 11);

+

+// Interrupt routine intialisation

+// channel A and B callbacks

+void doA(){sensor.handleA();}

+void doB(){sensor.handleB();}

+void doC(){sensor.handleC();}

+

+

+// voltage set point variable

+float target_voltage = 1;

+

+// instantiate the commander

+Commander command = Commander(Serial);

+void doTarget(char* cmd) { command.scalar(&target_voltage, cmd); }

+void calcKV(char* cmd) {

+ // calculate the KV

+ Serial.println(motor.shaft_velocity/motor.target*30.0f/_PI);

+

+}

+

+void setup() {

+

+ // initialize encoder sensor hardware

+ sensor.init();

+ sensor.enableInterrupts(doA, doB, doC);

+ // link the motor to the sensor

+ motor.linkSensor(&sensor);

+

+ // driver config

+ // IMPORTANT!

+ // make sure to set the correct power supply voltage [V]

+ driver.voltage_power_supply = 12;

+ driver.init();

+ // link driver

+ motor.linkDriver(&driver);

+

+ // aligning voltage

+ motor.voltage_sensor_align = 3;

+

+ // set motion control loop to be used

+ motor.controller = MotionControlType::torque;

+

+ // use monitoring with serial

+ Serial.begin(115200);

+ // comment out if not needed

+ motor.useMonitoring(Serial);

+

+ // initialize motor

+ motor.init();

+ // align sensor and start FOC

+ motor.initFOC();

+

+ // add target command T

+ command.add('T', doTarget, "target voltage");

+ command.add('K', calcKV, "calculate KV rating");

+

+ Serial.println(F("Motor ready."));

+ Serial.println(F("Set the target voltage : - commnad T"));

+ Serial.println(F("Calculate the motor KV : - command K"));

+ _delay(1000);

+}

+

+

+void loop() {

+

+ // main FOC algorithm function

+ // the faster you run this function the better

+ // Arduino UNO loop ~1kHz

+ // Bluepill loop ~10kHz

+ motor.loopFOC();

+

+ // Motion control function

+ // velocity, position or voltage (defined in motor.controller)

+ // this function can be run at much lower frequency than loopFOC() function

+ // You can also use motor.move() and set the motor.target in the code

+ motor.move(target_voltage);

+

+ // user communication

+ command.run();

+}

\ No newline at end of file

diff --git a/examples/utils/calibration/find_kv_rating/magnetic_sensor/find_kv_rating/find_kv_rating.ino b/examples/utils/calibration/find_kv_rating/magnetic_sensor/find_kv_rating/find_kv_rating.ino

new file mode 100644

index 00000000..f3dd74a1

--- /dev/null

+++ b/examples/utils/calibration/find_kv_rating/magnetic_sensor/find_kv_rating/find_kv_rating.ino

@@ -0,0 +1,96 @@

+/**

+ * Find KV rating for motor with magnetic sensors

+ *

+ * Motor KV rating is defiend as the increase of the motor velocity expressed in rotations per minute [rpm] per each 1 Volt int voltage control mode.

+ *

+ * This example will set your motor in the torque control mode using voltage and set 1 volt to the motor. By reading the velocity it will calculat the motors KV rating.

+ * - To make this esimation more credible you can try increasing the target voltage (or decrease in some cases)

+ * - The KV rating should be realatively static number - it should not change considerably with the increase in the voltage

+ */

+#include

+

+// magnetic sensor instance - SPI

+MagneticSensorSPI sensor = MagneticSensorSPI(AS5147_SPI, 10);

+// magnetic sensor instance - I2C

+// MagneticSensorI2C sensor = MagneticSensorI2C(AS5600_I2C);

+// magnetic sensor instance - analog output

+// MagneticSensorAnalog sensor = MagneticSensorAnalog(A1, 14, 1020);

+

+// BLDC motor & driver instance

+BLDCMotor motor = BLDCMotor(11);

+BLDCDriver3PWM driver = BLDCDriver3PWM(9, 5, 6, 8);

+// Stepper motor & driver instance

+//StepperMotor motor = StepperMotor(50);

+//StepperDriver4PWM driver = StepperDriver4PWM(9, 5, 10, 6, 8);

+

+// voltage set point variable

+float target_voltage = 1;

+

+// instantiate the commander

+Commander command = Commander(Serial);

+void doTarget(char* cmd) { command.scalar(&target_voltage, cmd); }

+void calcKV(char* cmd) {

+ // calculate the KV

+ Serial.println(motor.shaft_velocity/motor.target*30.0f/_PI);

+

+}

+

+void setup() {

+

+ // initialize encoder sensor hardware

+ sensor.init();

+ // link the motor to the sensor

+ motor.linkSensor(&sensor);

+

+ // driver config

+ // IMPORTANT!

+ // make sure to set the correct power supply voltage [V]

+ driver.voltage_power_supply = 12;

+ driver.init();

+ // link driver

+ motor.linkDriver(&driver);

+

+ // aligning voltage

+ motor.voltage_sensor_align = 3;

+

+ // set motion control loop to be used

+ motor.controller = MotionControlType::torque;

+

+ // use monitoring with serial

+ Serial.begin(115200);

+ // comment out if not needed

+ motor.useMonitoring(Serial);

+

+ // initialize motor

+ motor.init();

+ // align sensor and start FOC

+ motor.initFOC();

+

+ // add target command T

+ command.add('T', doTarget, "target voltage");

+ command.add('K', calcKV, "calculate KV rating");

+

+ Serial.println(F("Motor ready."));

+ Serial.println(F("Set the target voltage : - commnad T"));

+ Serial.println(F("Calculate the motor KV : - command K"));

+ _delay(1000);

+}

+

+

+void loop() {

+

+ // main FOC algorithm function

+ // the faster you run this function the better

+ // Arduino UNO loop ~1kHz

+ // Bluepill loop ~10kHz

+ motor.loopFOC();

+

+ // Motion control function

+ // velocity, position or voltage (defined in motor.controller)

+ // this function can be run at much lower frequency than loopFOC() function

+ // You can also use motor.move() and set the motor.target in the code

+ motor.move(target_voltage);

+

+ // user communication

+ command.run();

+}

\ No newline at end of file

diff --git a/examples/utils/calibration/find_pole_pair_number/encoder/find_pole_pairs_number/find_pole_pairs_number.ino b/examples/utils/calibration/find_pole_pair_number/encoder/find_pole_pairs_number/find_pole_pairs_number.ino

index c5dfbf43..aac879cd 100644

--- a/examples/utils/calibration/find_pole_pair_number/encoder/find_pole_pairs_number/find_pole_pairs_number.ino

+++ b/examples/utils/calibration/find_pole_pair_number/encoder/find_pole_pairs_number/find_pole_pairs_number.ino

@@ -56,7 +56,7 @@ void setup() {

Serial.println("-\n");

float pp_search_voltage = 4; // maximum power_supply_voltage/2

- float pp_search_angle = 6*M_PI; // search electrical angle to turn

+ float pp_search_angle = 6*_PI; // search electrical angle to turn

// move motor to the electrical angle 0

motor.controller = MotionControlType::angle_openloop;

@@ -73,6 +73,7 @@ void setup() {

while(motor_angle <= pp_search_angle){

motor_angle += 0.01f;

motor.move(motor_angle);

+ _delay(1);

}

_delay(1000);

// read the encoder value for 180

@@ -89,9 +90,9 @@ void setup() {

Serial.print(F("Estimated PP : "));

Serial.println(pp);

Serial.println(F("PP = Electrical angle / Encoder angle "));

- Serial.print(pp_search_angle*180/M_PI);

+ Serial.print(pp_search_angle*180/_PI);

Serial.print("/");

- Serial.print((angle_end-angle_begin)*180/M_PI);

+ Serial.print((angle_end-angle_begin)*180/_PI);

Serial.print(" = ");

Serial.println((pp_search_angle)/(angle_end-angle_begin));

Serial.println();

diff --git a/examples/utils/calibration/find_pole_pair_number/magnetic_sensor/find_pole_pairs_number/find_pole_pairs_number.ino b/examples/utils/calibration/find_pole_pair_number/magnetic_sensor/find_pole_pairs_number/find_pole_pairs_number.ino

index 0b07c772..e98a4529 100644

--- a/examples/utils/calibration/find_pole_pair_number/magnetic_sensor/find_pole_pairs_number/find_pole_pairs_number.ino

+++ b/examples/utils/calibration/find_pole_pair_number/magnetic_sensor/find_pole_pairs_number/find_pole_pairs_number.ino

@@ -55,7 +55,7 @@ void setup() {

Serial.println("-\n");

float pp_search_voltage = 4; // maximum power_supply_voltage/2

- float pp_search_angle = 6*M_PI; // search electrical angle to turn

+ float pp_search_angle = 6*_PI; // search electrical angle to turn

// move motor to the electrical angle 0

motor.controller = MotionControlType::angle_openloop;

@@ -73,6 +73,7 @@ void setup() {

motor_angle += 0.01f;

sensor.update(); // keep track of the overflow

motor.move(motor_angle);

+ _delay(1);

}

_delay(1000);

// read the sensor value for 180

@@ -89,9 +90,9 @@ void setup() {

Serial.print(F("Estimated PP : "));

Serial.println(pp);

Serial.println(F("PP = Electrical angle / Encoder angle "));

- Serial.print(pp_search_angle*180/M_PI);

+ Serial.print(pp_search_angle*180/_PI);

Serial.print(F("/"));

- Serial.print((angle_end-angle_begin)*180/M_PI);

+ Serial.print((angle_end-angle_begin)*180/_PI);

Serial.print(F(" = "));

Serial.println((pp_search_angle)/(angle_end-angle_begin));

Serial.println();

diff --git a/examples/utils/current_sense_test/generic_current_sense/generic_current_sense.ino b/examples/utils/current_sense_test/generic_current_sense/generic_current_sense.ino

new file mode 100644

index 00000000..e999de23

--- /dev/null

+++ b/examples/utils/current_sense_test/generic_current_sense/generic_current_sense.ino

@@ -0,0 +1,59 @@

+/**

+ * An example code for the generic current sensing implementation

+*/

+#include

+

+

+// user defined function for reading the phase currents

+// returning the value per phase in amps

+PhaseCurrent_s readCurrentSense(){

+ PhaseCurrent_s c;

+ // dummy example only reading analog pins

+ c.a = analogRead(A0);

+ c.b = analogRead(A1);

+ c.c = analogRead(A2); // if no 3rd current sense set it to 0

+ return(c);

+}

+

+// user defined function for intialising the current sense

+// it is optional and if provided it will be called in current_sense.init()

+void initCurrentSense(){

+ pinMode(A0,INPUT);

+ pinMode(A1,INPUT);

+ pinMode(A2,INPUT);

+}

+

+

+// GenericCurrentSense class constructor

+// it receives the user defined callback for reading the current sense

+// and optionally the user defined callback for current sense initialisation

+GenericCurrentSense current_sense = GenericCurrentSense(readCurrentSense, initCurrentSense);

+

+

+void setup() {

+ // if callbacks are not provided in the constructor

+ // they can be assigned directly:

+ //current_sense.readCallback = readCurrentSense;

+ //current_sense.initCallback = initCurrentSense;

+

+ // initialise the current sensing

+ current_sense.init();

+

+

+ Serial.begin(115200);

+ Serial.println("Current sense ready.");

+}

+

+void loop() {

+

+ PhaseCurrent_s currents = current_sense.getPhaseCurrents();

+ float current_magnitude = current_sense.getDCCurrent();

+

+ Serial.print(currents.a); // milli Amps

+ Serial.print("\t");

+ Serial.print(currents.b); // milli Amps

+ Serial.print("\t");

+ Serial.print(currents.c); // milli Amps

+ Serial.print("\t");

+ Serial.println(current_magnitude); // milli Amps

+}

\ No newline at end of file

diff --git a/examples/utils/sensor_test/generic_sensor/generic_sensor.ino b/examples/utils/sensor_test/generic_sensor/generic_sensor.ino

new file mode 100644

index 00000000..4a470e59

--- /dev/null

+++ b/examples/utils/sensor_test/generic_sensor/generic_sensor.ino

@@ -0,0 +1,51 @@

+/**

+ * Generic sensor example code

+ *

+ * This is a code intended to demonstrate how to implement the generic sensor class

+ *

+ */

+

+#include

+

+// sensor reading function example

+// for the magnetic sensor with analog communication

+// returning an angle in radians in between 0 and 2PI

+float readSensor(){

+ return analogRead(A0)*_2PI/1024.0;

+}

+

+// sensor intialising function

+void initSensor(){

+ pinMode(A0,INPUT);

+}

+

+// generic sensor class contructor

+// - read sensor callback

+// - init sensor callback (optional)

+GenericSensor sensor = GenericSensor(readSensor, initSensor);

+

+void setup() {

+ // monitoring port

+ Serial.begin(115200);

+

+ // if callbacks are not provided in the constructor

+ // they can be assigned directly:

+ //sensor.readCallback = readSensor;

+ //sensor.initCallback = initSensor;

+

+ sensor.init();

+

+ Serial.println("Sensor ready");

+ _delay(1000);

+}

+

+void loop() {

+ // iterative function updating the sensor internal variables

+ // it is usually called in motor.loopFOC()

+ sensor.update();

+

+ // display the angle and the angular velocity to the terminal

+ Serial.print(sensor.getAngle());

+ Serial.print("\t");

+ Serial.println(sensor.getVelocity());

+}

\ No newline at end of file

diff --git a/examples/utils/sensor_test/linear_hall_sensors/find_raw_centers/find_raw_centers.ino b/examples/utils/sensor_test/linear_hall_sensors/find_raw_centers/find_raw_centers.ino

new file mode 100644

index 00000000..5fda5f59

--- /dev/null

+++ b/examples/utils/sensor_test/linear_hall_sensors/find_raw_centers/find_raw_centers.ino

@@ -0,0 +1,62 @@

+/**

+ * An example to find the center offsets for both ADC channels used in the LinearHall sensor constructor

+ * Spin your motor through at least one full revolution to average out all of the variations in magnet strength.

+ */

+

+//Change these defines to match the analog input pins that your hall sensors are connected to

+#define LINEAR_HALL_CHANNEL_A 39

+#define LINEAR_HALL_CHANNEL_B 33

+

+

+//program variables

+int minA, maxA, minB, maxB, centerA, centerB;

+unsigned long timestamp;

+

+void setup() {

+ // monitoring port

+ Serial.begin(115200);

+

+ // initialise magnetic sensor hardware

+ pinMode(LINEAR_HALL_CHANNEL_A, INPUT);

+ pinMode(LINEAR_HALL_CHANNEL_B, INPUT);

+

+ minA = analogRead(LINEAR_HALL_CHANNEL_A);

+ maxA = minA;

+ centerA = (minA + maxA) / 2;

+ minB = analogRead(LINEAR_HALL_CHANNEL_B);

+ maxB = minB;

+ centerB = (minB + maxB) / 2;

+

+ Serial.println("Sensor ready");

+ delay(1000);

+ timestamp = millis();

+}

+

+void loop() {

+ //read sensors and update variables

+ int tempA = analogRead(LINEAR_HALL_CHANNEL_A);

+ if (tempA < minA) minA = tempA;

+ if (tempA > maxA) maxA = tempA;

+ centerA = (minA + maxA) / 2;

+ int tempB = analogRead(LINEAR_HALL_CHANNEL_B);

+ if (tempB < minB) minB = tempB;

+ if (tempB > maxB) maxB = tempB;

+ centerB = (minB + maxB) / 2;

+

+ if (millis() > timestamp + 100) {

+ timestamp = millis();

+ // display the center counts, and max and min count

+ Serial.print("A:");

+ Serial.print(centerA);

+ Serial.print("\t, B:");

+ Serial.print(centerB);

+ Serial.print("\t, min A:");

+ Serial.print(minA);

+ Serial.print("\t, max A:");

+ Serial.print(maxA);

+ Serial.print("\t, min B:");

+ Serial.print(minB);

+ Serial.print("\t, max B:");

+ Serial.println(maxB);

+ }

+}

diff --git a/examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_i2c/magnetic_sensor_i2c_dual_bus_examples/esp32_i2c_dual_bus_example/esp32_i2c_dual_bus_example.ino b/examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_i2c/magnetic_sensor_i2c_dual_bus_examples/esp32_i2c_dual_bus_example/esp32_i2c_dual_bus_example.ino

index c930437b..0516ede1 100644

--- a/examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_i2c/magnetic_sensor_i2c_dual_bus_examples/esp32_i2c_dual_bus_example/esp32_i2c_dual_bus_example.ino

+++ b/examples/utils/sensor_test/magnetic_sensors/magnetic_sensor_i2c/magnetic_sensor_i2c_dual_bus_examples/esp32_i2c_dual_bus_example/esp32_i2c_dual_bus_example.ino

@@ -18,7 +18,7 @@ void setup() {

// Normally SimpleFOC will call begin for i2c but with esp32 begin() is the only way to set pins!

// It seems safe to call begin multiple times

- Wire1.begin(19, 23, 400000);

+ Wire1.begin(19, 23, (uint32_t)400000);

sensor0.init();

sensor1.init(&Wire1);

diff --git a/keywords.txt b/keywords.txt

index b47c18fd..e6f4e605 100644

--- a/keywords.txt

+++ b/keywords.txt

@@ -22,7 +22,9 @@ LowsideCurrentSense KEYWORD1

CurrentSense KEYWORD1

Commander KEYWORD1

StepDirListener KEYWORD1

-

+GenericCurrentSense KEYWORD1

+GenericSensor KEYWORD1

+SimpleFOCDebug KEYWORD1

initFOC KEYWORD2

loopFOC KEYWORD2

@@ -89,7 +91,7 @@ getFOCCurrents KEYWORD2

getDCCurrent KEYWORD2

setPwm KEYWORD2

driverAlign KEYWORD2

-driverSync KEYWORD2

+linkDriver KEYWORD2

add KEYWORD2

run KEYWORD2

attach KEYWORD2

@@ -102,6 +104,8 @@ lpf KEYWORD2

motor KEYWORD2

handlePWM KEYWORD2

enableInterrupt KEYWORD2

+readCallback KEYWORD2

+initCallback KEYWORD2

@@ -118,6 +122,7 @@ pullup KEYWORD2

quadrature KEYWORD2

foc_modulation KEYWORD2

target KEYWORD2

+motion KEYWORD2

pwm_frequency KEYWORD2

dead_zone KEYWORD2

gain_a KEYWORD2

@@ -230,6 +235,7 @@ _PI_3 LITERAL1

_SQRT3 LITERAL1

_PI LITERAL1

_HIGH_Z LITERAL1

+_NC LITERAL1

_MON_TARGET LITERAL1

_MON_VOLT_Q LITERAL1

diff --git a/library.properties b/library.properties

index 89540636..d4b639d5 100644

--- a/library.properties

+++ b/library.properties

@@ -1,5 +1,5 @@

name=Simple FOC

-version=2.2

+version=2.2.2

author=Simplefoc

maintainer=Simplefoc

sentence=A library demistifying FOC for BLDC motors

diff --git a/src/BLDCMotor.cpp b/src/BLDCMotor.cpp

index ff451e07..c417e684 100644

--- a/src/BLDCMotor.cpp

+++ b/src/BLDCMotor.cpp

@@ -1,15 +1,20 @@

#include "BLDCMotor.h"

+#include "./communication/SimpleFOCDebug.h"

// BLDCMotor( int pp , float R)

// - pp - pole pair number

// - R - motor phase resistance

-BLDCMotor::BLDCMotor(int pp, float _R)

+// - KV - motor kv rating (rmp/v)

+BLDCMotor::BLDCMotor(int pp, float _R, float _KV)

: FOCMotor()

{

// save pole pairs number

pole_pairs = pp;

// save phase resistance number

phase_resistance = _R;

+ // save back emf constant KV = 1/KV

+ KV_rating = _KV;

+

// torque control type is voltage by default

torque_controller = TorqueControlType::voltage;

}

@@ -24,14 +29,14 @@ void BLDCMotor::linkDriver(BLDCDriver* _driver) {

// init hardware pins

void BLDCMotor::init() {

- if(monitor_port) monitor_port->println(F("MOT: Init"));

-

- // if no current sensing and the user has set the phase resistance of the motor use current limit to calculate the voltage limit

- if( !current_sense && _isset(phase_resistance)) {

- float new_voltage_limit = current_limit * (phase_resistance); // v_lim = current_lim / (3/2 phase resistance) - worst case

- // use it if it is less then voltage_limit set by the user

- voltage_limit = new_voltage_limit < voltage_limit ? new_voltage_limit : voltage_limit;

+ if (!driver || !driver->initialized) {

+ motor_status = FOCMotorStatus::motor_init_failed;

+ SIMPLEFOC_DEBUG("MOT: Init not possible, driver not initialized");

+ return;

}

+ motor_status = FOCMotorStatus::motor_initializing;

+ SIMPLEFOC_DEBUG("MOT: Init");

+

// sanity check for the voltage limit configuration

if(voltage_limit > driver->voltage_limit) voltage_limit = driver->voltage_limit;

// constrain voltage for sensor alignment

@@ -42,20 +47,22 @@ void BLDCMotor::init() {