-

Notifications

You must be signed in to change notification settings - Fork 80

New issue

Have a question about this project? Sign up for a free GitHub account to open an issue and contact its maintainers and the community.

By clicking “Sign up for GitHub”, you agree to our terms of service and privacy statement. We’ll occasionally send you account related emails.

Already on GitHub? Sign in to your account

Provisional release notes for CR-6 community firmware release 5 beta #84

Comments

|

“ Enable G29 bed leveling mesh validation tool” may be typo? |

|

Fixed it. Thanks for proof reading it. |

Thank you for writing such complete and readable documentation. I hope more people take the time to read it before posting issues that are already answered therein. |

You and me both, mate 😉 |

|

“ Pre-heat PLA and ABS temperatures are properly shown in the touch screen interface” |

|

"Heaters are turned off when the actual probe is done to decrease electrical noise, which then causes Z-offset and bed leveling inaccuracies" I find that phrasing to be ambiguous. "Heaters are turned off while the actual probing is done. This reduces electrical noise which may otherwise cause inaccuracies in the Z-Offset and Bed Leveling measurements." |

|

Thanks, updated it |

|

Good write-up! Support M701/M702 filament load/unload. With @grobux changing it to Extrude/Retract the terminology should be part of the sentence. |

|

“ If you go to the home/info screen though, you can see it heats ups though.” |

|

“ After flashing go to the menu and reset to factory settings or issue M502 followed by M500 in Octoprint - do this also if you have been running an earlier release. You need to relevel the bed, reset the z-offset, and reprogram esteps (if you've changed them from defaults).” I recommend you add “redo PID” to the list of things to be done after flashing, in step 8. I use M303 E0 S205 U and M303 E-1 S50 U routinely after M502. The U saves me having to enter the PID parameters, and could be coded into a small .gcode file to print from the SD card if people don’t use their serial port. |

|

Since G28 now turns off the heaters while probing, and some folks have G28 in their start code, it might help folks to include some advice about reconfiguring their starting gcode to move M109 to after G28 in their start code, if they are currently using Cura and/or M109. It may even be appreciated if you add a section wth recommended start and stop gcoding with explanations. |

That. I assume that a recommendation of start and stop GCode will reduce the support requests :) |

I'Il add a link to this page - but that G28 cools down after or overrides temperatures is a blocker IMHO, we can't ask people to reslice their stuff. edit: Opened bug #90 for that.

Load/unload is the gcode description - it is unrelated to the touch screen |

That is a great resource page.

Maybe I am different that way - I slice every time. I don't maintain an inventory of past gcodes that I would not want to "reslice". |

|

I've made some additional changes and added some imagery. |

|

Hi, I really would like to try the release 5 beta but for some reason I am missing the point on how to download the files. I can't see the 'assets' section :-( Hope you will be able to explain to me. Thanks in advance |

These a pre-release notes. There are no assets yet, because it is not released yet. If you would like a early look at CF5, you can find a developmental version on their Discord channel. https://discord.com/channels/759603746270609428/791082544899555358 |

|

I tried this and it resolved several issues - Z-offset is now saved after reboot, but only when set from the main menu, not the value adjusted during print - could this be also be saved permanently? Also I used to set my z-offset to 0.15-0.2, now it's down to 0.1 for correct squish, is this the result of "improved homing accuracy"? The second issue I noticed is connected to the heater turned off during homing. Because it takes so long my nozzle temp can drop drastically before the print starts, especially in a cold room (it's winter here). Basically the nozzle preheats to 200'C, then homes and by the time it starts extruding the line on the right it's down to about 170'c. With large prints it has enough time to get back to the working temp on skirt, but printing a small item can be problematic. Does turning off the heater during homing really improve accuracy that much? I've never had issues with it before, so I'm not sure if the tradeoff is worth it. Please let me know if you'd like me to log it as a bug or FR separately. |

|

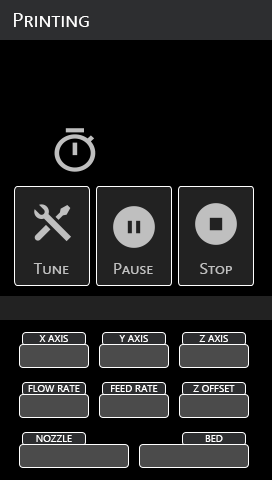

With Flow Rate and Feed Rate both now having the same speedometer icons, and both being measured in %, it makes the footer display less clear. Might want to consider a way to clarify that? |

This is your cue @grobux 😀 |

|

Your comment is on point, I'm already thinking about a new design for the footer. There is much more infos to display than before, and the current design isn't suited. |

I kept things pretty basic and replaced icons with labels, as I'm lacking space and creativity (for now at least). The branch Raw preview: |

|

Feel free to go on icon hunt @Thinkersbluff 😉 |

|

Is the fan speed missing/required on this screen? |

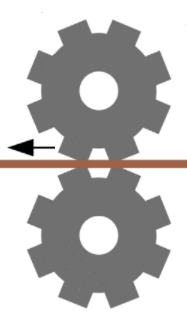

Inspired by Fig 3 in this article: https://link.springer.com/article/10.1007/s40430-020-02610-0 If something like this is readable at the desired scale, it may also work for Flow Rate? |

|

Let's release this baby. |

First of all I want to thank everyone who has been testing the alpha 4 release of the community firmware. All the testing and feedback has made this firmware better and better. This is truly a community firmware.

In the period between then and now, my Creality CR-6 has died and from its ashes it became alive once again with a BigTreeTech SKR CR-6 board. A while later I also received a new Creality CR-6 SE with the v4.5.3 motherboard. It took a while for that one to arrive, then a while for the firmware source code to be released, so it has caused some delays to get real work done. Yet, some users were able to test some fixes I was able to do without a operational printer.

TL;DR: CR-6 MAX support, SD card folder support, better Octoprint support, BigTreeTech SKR CR-6 support, native and improved filament sensor support, many stability and ABL accuracy improvements, rebased on latest Marlin, and enabled the watchdog safety feature

Table of contents

Special thanks to...

If you like to contribute to the community firmware, in one way or the other, please check the home page of the Creality CR-6 community firmware.

Other news

Major features across firmware editions

Note: This is still a beta formally - because this is based on a unreleased version of Marlin. However, thanks to the amount of effort that has gone into it, I'm confident it should be a pretty stable release!

Safety

Important safety feature: We now enabled the watchdog for STM32F1 processors - if Marlin would freeze from some reason (like due to SD card issues) the printer is automatically reset and the heaters are disabled - this feature is not enabled on the stock Creality or BTT firmware

User interface

This release features an entirely refreshed user interface by @grobux! Improved font spacing, improved graphics. JPEG artifacts be gone!

In addition we implemented toggles allowing you to decide if you want to hear sounds from the touch screen (or not), and if you like the touch screen display to dim to 10% on idle (30 seconds currently).

We've also implemented that you can tune the flow rate (the amount of filament extruded) during the print from the "tuning" screen. Very useful when tuning in new filaments. You can also control and review the fan speed percentage from the tuning screen.

You can also now quickly set the bed and hot-end temperature by tapping the temperature in the footer.

On the print screen we've added displays for the fan speed, flow rate, and X/Y/Z axis positions:

On this screen you can also set the hotend and bed temperature by directly tapping the numbers.

SD card folder support

We support navigation through folders on your SD card. No longer are you limited to 5 pages of gcode files. You can organise your SD card in folders.

Hardware support

Octoprint

We have improved Octoprint support. We show the printer status messages also on the home screen.

The filament sensor is working and Octoprint acts on it - it pauses the print. Make sure you have the correct gcode in Octoprint so it parks the nozzle.

In addition when an Octoprint print starts we automatically show the "printing" screen with full access to all details and tuning options. You can also set the print progress using the the detailed progress plugin.

Reliability

PREHEAT_BEFORE_PROBINGandPROBING_HEATERS_OFFin the firmware configurationDetailed Changes

M420 S1beforeG26bed leveling mesh validation toolChanges specific when using Creality v4.5.2 and v4.5.3 motherboards

Changes specific when using the Creality stock display

Changes specific to BTT SKR CR6 boards

FAN_KICKSTART_TIMEto ensure the part cooling fan is started reliablyChanges specific to BTT SKR CR6 firmware with BTT TFT

M205Comparison to Creality firmware

See for a full list the Community firmware 4 alpha release notes, but some highlights here:

Allow the probe offset to be set in 0.01mm offsets (issue Increase Z-Offset Resolution in the Level Screen to 0.01 #15)

Pre-heat PLA and PETG temperatures are properly shown in the touch screen interface

Save power loss recovery settings to the SD card instead of EEPROM, preventing blobs

Filament runout detection has now been enabled by default again. (issue Change in default for runout sensor is a breaking change, makes old slices missing runout detection #19)

M412 S0- otherwise you can enable it usingM412 S1.Support

M300(play tone / buzzer) (issue [FR] Add M300 (Play Tone) support #20) - You can now let your printer make some noise! Note that we only support the duration parameter of M300, and only with 8 millisecond precision due to the touch screen limitation.Support

M73(print progress) (issue #7 and issue [BUG] Support print progress display #27)Support

M75/M77(start/stop print timer) on the touch screen level. This can be useful if printing from a host, because if you issue this gcode, the touch screen changes to the print progress screen. When printing from Octoprint, this will be injected by default in my experience.Enable EMERGENCY_PARSER commands

Support

M117LCD message (issue #7) on the print progress screenEnable linear advance / pressure advance allowing you to do linear advance calibration

Based on recent version of Marlin (as mentioned above) instead of an early version of Marlin 2.0.0

Support

ADVANCED_PAUSE_FEATUREM600filament change - please read here how to use itM701/M702filament load/unloadSome bugs fixed

Some bugs may be fixed in the Creality v2.x firmware too - this list compares to the Creality v1.0.3.7 firmware on which the BTT SKR firmware is also based.

G1 X0 Y{machine_depth} ;Present printto your end gcode in Cura to put the bed forward after the print completes.Known issues

G29from your start gcode - there is no need to level every time you print. Check this page for a recommended start gcode for your slicer. Alternatively if you're tech-savvy, you can undefinePREHEAT_BEFORE_PROBINGin the Configuration.h.When using the Creality stock touch screen:

For the BTT SKR CR6 board:

EMERGENCY_PARSERsupport is not available due to upstream bug #19623 - so the commands likeM112will be executed in order. This issue is also present in the stock firmware.Features not available in this firmware

Flashing instructions

Note: This release is accompanied by a new firmware for the touch screen. This release and the new touch screen firmware goes hand-in-hand - one cannot be used without the other.

Touch screen flashing instructions

This release of the touch screen firmware comes with a new version of DGUS OS (the underlying operating system of the touch screen) to fix text rendering issues.

Flashing instructions are also available as a video - this video is for the Ender 3 V2 but the same procedure applies to the CR-6. For instructions, check the README.txt in the touch screen firmware download.

For this release the touch screen firmware and flashing instructions is included in the firmware release package. Be sure to follow the instructions carefully. If you experience issues, try flashing the touch screen a second or even a third time. It doesn't always "take" all the files. Sorry - hardware limitation!

Mainboard / Marlin flashing instructions

M503in a serial monitor.M997from Octoprint/Pronterface.firmware.binfile tofirmware.cur.M115or going to "Control -> Info" on the touch screen.M502followed byM500in Octoprint - do this also if you have been running an earlier release. You need to relevel the bed, recalibrate the z-offset, reprogram esteps (if you've changed them from defaults), and do a PID tune (if you find that the heating is not reliable for you or if you use high temperature plastics like ABS and nylon).File listing

The files can be downloaded from the assets section at the bottom of the page. You can find the description of the files below.

As mentioned above, while touching the bed we turn off the hot-end momentarily. If you don't want that, you can use the builds below. Only use these if you have a good reason to do so.

Note: The files with

ProbeHeaterOnkeeps the hot-end heated while probing - in our experience this decreases bed leveling accuracy and cause a drifing Z-offset - but some people prefer it this way. You have a choice.Rollback instructions

To completely roll back to an earlier release:

FAQ

Some frequently asked questions. Your question will most likely be answered here!

How do I know if I have a Creality v4.5.2 or v4.5.3 motherboard?

Does it matter if I flash the touch screen or motherboard firmware first?

No - you can do it in either order.

I'm having trouble flashing the touch screen firmware / things aren't working / I'm seeing garbled or missing text

Try reflashing your touch screen firmware. Read the flashing instructions carefully. The DWIN stock touch screen is very picky when it comes to SD cards. Sorry, we nor Creality can't change this.

After flashing the touch screen it only shows a black display

This has occurred to some users while upgrading to either official or community firmware, but it is unclear why this happens.

Make sure you haven't accidentally shorted the PCB of the touch screen when you attempted to flash it. Because the DWIN touch screen uses SRAM, it takes a while for the error condition to clear. Turn off the printer for 5 minutes or more and try reflashing the touch screen.

My stepper motors run the wrong way (BTT SKR CR6 board only)

There has been one report for the BTT SKR CR6 board by which the stepper motor turns the wrong way. You need to compile the firmware yourself. For most users the direction is correct though.

Reporting issues

Please follow the instructions here carefully.

Troubleshooting

Verify that the issues are not in your hardware. We've seen issues that were reported as firmware issues, but were actually hardware issues that "just" happened.

Verify that the issues are not in your slicer

Feature requests

Feature requests are welcome! Let us know in the issue tracker!

Contibuting

Your contributions are very welcome!

Some final notes

The CR-6 community firmware team wishes you a happy and healthy 2021!

Downloads below - find the correct download in the file listing above

The text was updated successfully, but these errors were encountered: