-

Notifications

You must be signed in to change notification settings - Fork 1

FLYN17 5

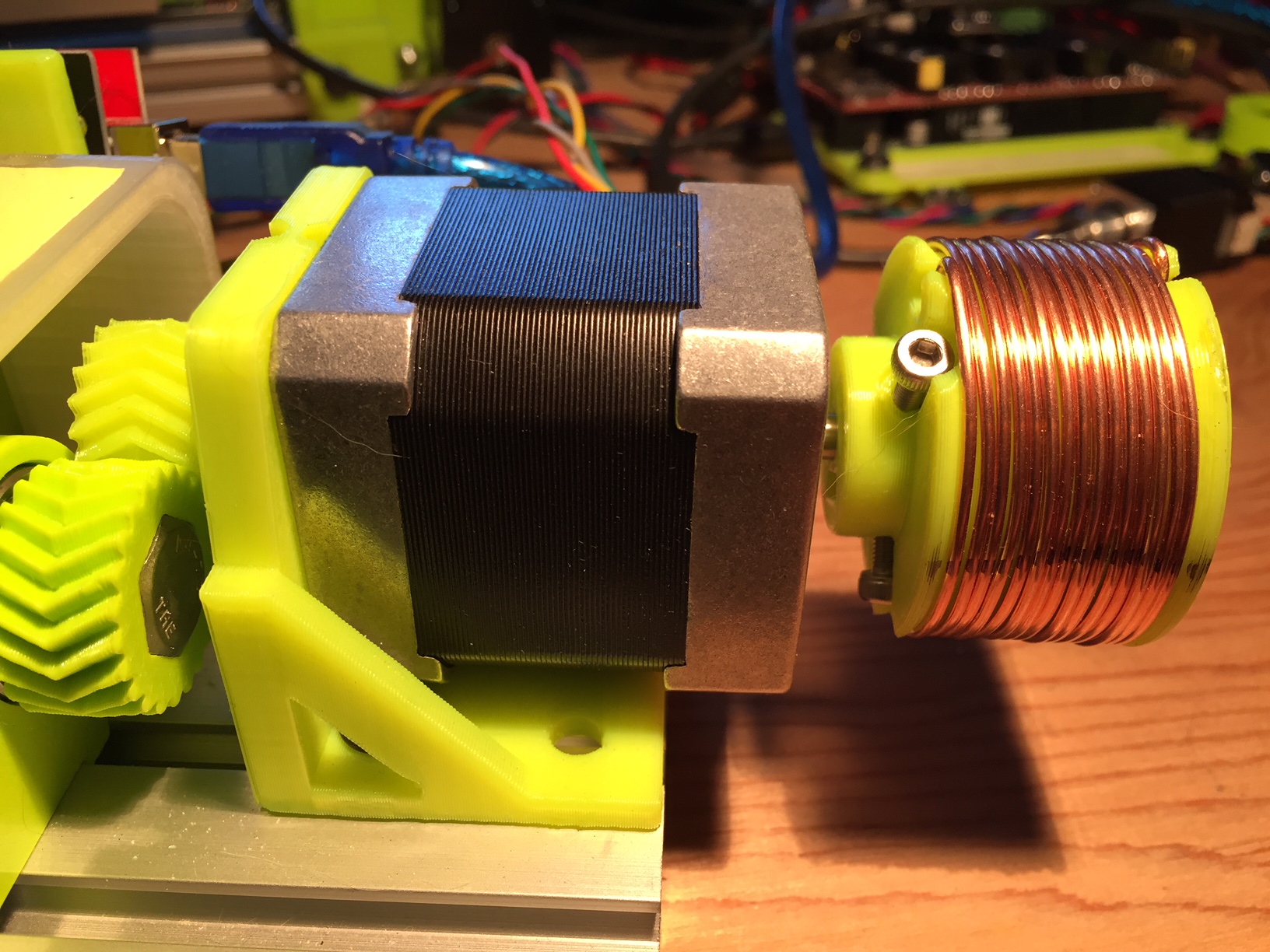

Flywheel mounted on stepper driveshaft counteracts mid-band resonances and load force irregularities by absorbing and restoring angular momentum to attached drive system. A typical dual-shaft NEMA17 stepper rotor has angular inertia of 82g/cm2. FLYN17-5 contributes approximately 80g/cm2 additional angular inertia when wrapped with 15 turns of 16ga (1.29mm) copper wire. Heavier wire can be used as required. Copper is recommended for its density but thicker steel wire can be used as well.

Flywheel has an inner shaft taper that centers the flywheel with the shaft. It also has three M3 set screws that lock the flywheel in place and provide additional centering adjustment.

Two deep notches in the flywheel allow copper wire to be fastened with a simple hook bent into each end of the wire.

Flywheels make a difference...

Assembly is straightforward except for the wire, which has to be wrapped carefully around the flywheel. Since the wire is springy, you will need to hold it in place as you wrap it.

- Bend a 3mm hook into the end of the wire

- Insert hook into flywheel notch

- Wrap the wire smoothly and tightly around the flywheel (about 15 turns)

- Hold the wire in place and cut it with enough excess to form another hook

- Bend the second hook in the wire and hook it into the notch

NOTE: If you need to replace the flywheel, you can re-use the wire by simply unhooking it and re-attaching it to another flywheel.

Slide the flywheel onto the rear shaft of your dual shaft stepper motor. The flywheel will pinch the end of the shaft. Tighten the M3 screws until they touch the shaft. Inspect the flywheel as you turn it slowly--use the M3 screws to align the inside of the flywheel. Once aligned, you can tap the flywheel to be close to but not touching the stepper. The M3 screws will preserve flywheel alignment.

Once the flywheel is centered, tighten each screw just a bit and move on to the next screw. Repeat this for many revolutions and you'll be ready to spin up your stepper.