-

Notifications

You must be signed in to change notification settings - Fork 2

Home

Welcome to Day 1 of the 2021 UK-RAS Manufacturing Robotics Challenge!

This Wiki contains all the material for the Day 1 ROS Training. This is a three-part crash course in ROS (the Robot Operating System), designed to get you up to speed with how to programme robots using the ROS framework, which you will use for the actual team robotics challenge over the following two days. You may already know how to use ROS, in which case great - skip ahead to the exercises or put your feet up! If you haven't used ROS before then don't worry - this course is designed for beginners!

This training was put together by Tom Howard and Alex Lucas, University Teaching Associates in Robotics at The University of Sheffield.

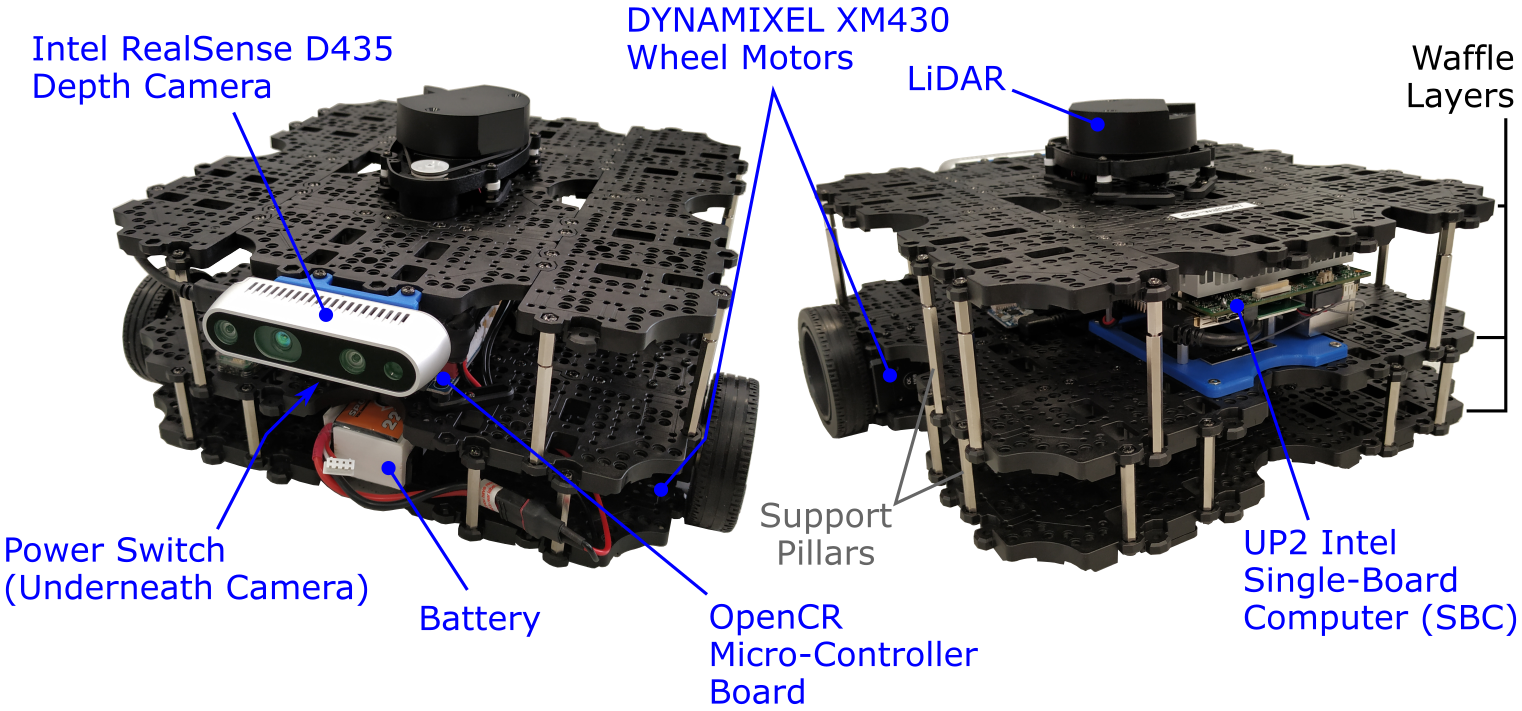

In Parts 1 and 2, you will be working with a simulated version of the TurtleBot3 Waffle made by Robotis. This is the 3rd generation robot in the TurtleBot Family, which has been the reference hardware platform for ROS since 2010. It's therefore a great robot to use to learn ROS and at the University of Sheffield we have a number of TurtleBot3 Waffle Robots specifically for this:

...but unfortunately you won't get to play with the real thing on this occasion, sorry!

You can see one of these robots in action in this video and there's a bit more detail about them below too, so that you don't feel like you're missing out too much:

Specifications:

- Independent left and right wheel motors (DYNAMIXEL XM430’s) to drive the robot using a differential drive configuration.

- An OpenCR Micro-Controller Board to power and control the wheel motors, distribute power to other hardware elements and provide an interface for additional sensors.

- An UP Squared Single-Board Computer (SBC) with an Intel Processor and 32GB on-board eMMC storage. This acts as the "brain" of the robot.

- A Light Detection and Ranging (or LiDAR) sensor, which spins continuously when the robot is in operation. This uses light in the form of laser pulses to allow the robot to measure the distance to surrounding objects and provides the robot with a 360° view of its environment.

- An Intel RealSense D435 Camera with left and right imaging sensors, allowing depth sensing as well as standard image capture

- A 9-Axis Inertial Measurement Unit (or IMU) on-board the OpenCR Micro Controller board, which uses an accelerometer, gyroscope and magnetometer to measure the robot’s specific force, acceleration, and orientation.

- Encoders in each of the DYNAMIXEL wheel motors, allowing measurement of speed and rotation count for each of the wheels

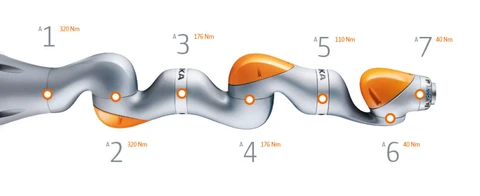

In Part 3 of this tutorial (and in the actual challenge!) you will be working with KUKA's LBR iiwa robotic arm. KUKA is well-known manufacturer of industrial robots and solutions for factory automation, and LBR iiwa is the first series-produced industrial robot (premiered in 2013), aimed specifically at safe Human-Robot Collaboration (HRC). LBR stands for "Leichtbauroboter" (German for lightweight robot), iiwa for "intelligent industrial work assistant".

Photo: KUKA

Image: Clearpath Robotics

Features:

- Integrated torque sensors in all 7 axes for safe HRC. Thanks to this, the LBR iiwa can detect contact immediately and reduces its level of force and speed instantly.

- Three controller options

- Position controller: conventional movement to the desired position with the programmed velocity

- Gravity compensation controller: compensating the weight of the load precisely so that it can be moved by exerting a minimum of external force.

- Compliance controller: compliance of the LBR iiwa can be configured both translationally and rotationally for all axes separately, thus optimizing adaptation of the characteristics of the robot to the specific task. It is also possible to activate a defined force and superpose it on a motion.

- The robot arm is available in two versions with payload capacities of 7 and 14 kilograms. We will use the 14 kg version, or "iiwa14", as it is referred in the code.

- High precision and repeatability of movements (± 0.1mm).

- Flexibility in the choice of end effectors.

Head to the Getting Started page to find out how to access the ROS Training Environment for this course.

Navigating This Wiki:

Getting Started →

ROS Training

UK-RAS Manufacturing Robotics Challenge 2021

Tom Howard & Alex Lucas | The University of Sheffield